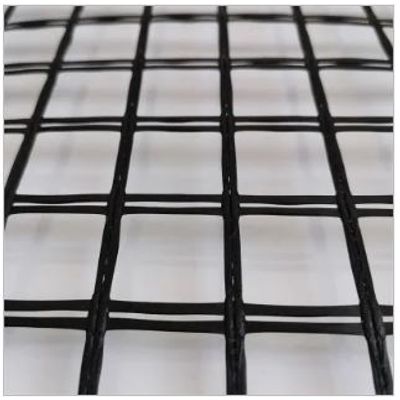

Youxin - Fiberglass Geogrid for Asphalt Reinforcement

Introducing our Fiberglass Geogrid for Asphalt Reinforcement, designed for optimal performance in road construction. Available in black, with lengths ranging from 50 to 100m and widths of 2, 3.95, or 5.9m, it features a durable asphalt coating. This high-quality material offers customizable dimensions and ensures longevity with a warranty of over 5 years.

Basic Product Information:

- Category: Geogrids

- Color: Black

- Length: Available in rolls of 50m to 100m

- Width: Options available at 2m, 3.95m, and 5.9m

- Coating: Asphalt

Usage Scenarios:

Fiberglass geogrids are primarily utilized for road asphalt reinforcement. This product is designed to enhance the durability and lifespan of asphalt paving projects by improving structural integrity and load distribution. Ideal for:

- High-traffic roadways

- Parking lots

- Airport runways

- Urban streets

- Industrial sites

- Bridge approaches

Product Overview: The Fiberglass Geogrid for Asphalt Reinforcement is a vital component in modern civil engineering and construction. It is engineered to provide superior performance in stress distribution and load transfer, which is essential in mitigating pavement cracking and extending the life of asphalt surfaces.

Installation Guide:

For optimal results, it is essential to follow proper installation procedures when using fiberglass geogrids:

-

Preparation of Subgrade: Ensure that the subgrade is clean, compacted, and free of debris. This step is critical for preventing future failures.

-

Placement of Geogrid: Roll out the geogrid over the prepared surface, ensuring that it lies flat without wrinkles or overlaps. You may fix the geogrid in place using stakes or pins to maintain its position.

-

Application of Asphalt: Once the geogrid is laid down, pour the asphalt mixture over it while ensuring even coverage. The hot asphalt will bond with the geogrid, establishing a strong mechanical connection.

-

Compaction: After laying the asphalt, it is crucial to compact the surface properly. This ensures that the asphalt envelops the geogrid, enhancing the overall strength of the paved structure.

To maintain the effectiveness of the fiberglass geogrid and the asphalt surface, routine inspections and maintenance are advised:

- Periodic Inspections: Regularly inspect the surface for signs of distress, such as cracking or rutting, and address issues promptly.

- Maintenance Work: Carry out necessary repairs and maintenance on the asphalt surface to prolong its lifespan. Removing debris and ensuring proper drainage can further enhance performance.

The Fiberglass Geogrid for Asphalt Reinforcement presents an innovative solution for the modern construction industry, combining advanced materials with practical design to enhance road performance. By utilizing this geogrid, construction projects can achieve greater longevity, stability, and safety, making it an essential component for effective asphalt reinforcement.

For inquiries, custom orders, or further information, please reach out to our sales team. We are committed to providing high-quality geogrid solutions tailored to your project`s specific needs.

-

High-Quality Material: The primary component of this geogrid is high-strength fiberglass, which is renowned for its excellent tensile strength and durability. This ensures that the geogrid can withstand harsh environmental conditions and heavy loads.

-

Customizable Dimensions: We recognize that different projects have varying requirements. Therefore, we offer customizable dimensions, allowing our customers to select the length and width that best suit their specific needs.

-

Enhanced Load Distribution: The fiberglass geogrid is designed to distribute loads evenly across the paved surface. By spreading the weight of traffic, it helps to prevent premature rutting and cracking, ensuring that the paved surface remains intact for longer periods.

-

Improved Asphalt Adhesion: The asphalt coating on the geogrid enhances the bond between the geogrid and the asphalt layer. This results in less slippage and greater composite action, further improving the performance and durability of the road.

-

Environmentally Friendly: Made from recyclable materials, the fiberglass geogrid contributes to sustainable construction practices. Its use can significantly reduce the amount of asphalt needed for repairs, thus minimizing environmental impact.

-

Warranty: The product comes with a warranty of more than 5 years, instilling confidence in its long-term performance. This warranty demonstrates our commitment to quality and customer satisfaction.

- Material: Fiberglass

- Weight: Approximately 70-120 g/m² (varies based on dimension and coating)

- Tensile Strength: High tensile strength ranging from 25 to 50 kN/m, depending on the specifications chosen.

- Temperature Resistance: Can withstand temperatures ranging from -30 to 80 degrees Celsius, making it suitable for various climates.