- Home

- Companies

- Top Organic Fertilizer Machines Factory

- Products

- YUSHUNXIN - Model SXZGZ-1560 - Rotary ...

YUSHUNXIN - Model SXZGZ-1560 -Rotary Drum Granulator

Are you looking for a granulator for large scale fertilizer production? Do you want to prepare large scale fertilizer pellets with low energy consumption? Rotary drum granulator can fully meet your requirements. It adopts wet granulation method, which uses liquid as binders to enhance the cohesive force between materials to turn fertilizer powder into granules. So it can help you make quality fertilizer. In addition, in order to produce fertilizer granules more smoothly, we especially upgrade its inside designs of reducing the possibility of wall sticking and improving the efficiency of granulation. Therefore, it can be used not only in compound fertilizer manufacturing but also organic fertilizer making. What`s more, combing with other fertilizer machines, it can help you set up a fertilizer granulation plant to make more profits!

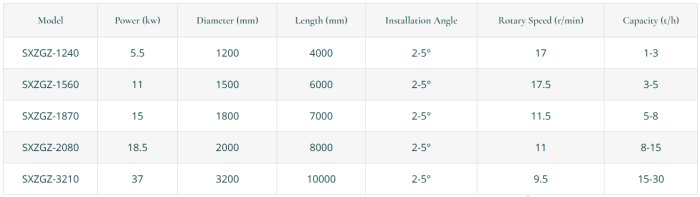

Both pan pellet equipment and double roller granulator are more suitable for small scale fertilizer granulation. Then how to make chemical powder into pellet in a large scale? Using rotary drum granulation machine is an ideal choice. Besides models for small scale granulation, we also design various types of drum granulators for mass production of compound fertilizer granules. For example, when you want to produce 8-15 tons of pellets per hour, we can provide you with SXZG-2080. Moreover, for larger scale fertilizer pellets manufacturing, you can choose SXZGZ-3210, which has capacity of 15-30 t/h.

Can drum fertilizer pelletizer produce particles with a diameter you need? Of course. Usually, thi s pellet making machine can make chemical powder into pellets within 3-6 mm. Which is commonly used in agriculture. Then how to regulate the size of granular fertilizer during rotary granulation? Adjust moisture content or control the rotating speed of the drum. The higher the water content, the larger the size; the lower the water content, the smaller the size. The higher the rotating speed, the smaller the size; the lower the rotating speed, the larger the size.

How about the energy consumption of rotary drum granulation? There is no doubt that it is a low energy consumption fertilizer granulation machine. The power of our largest drum granulator, which has an output of 15-30 t/h, is only 37 kw.