Zanni Group

- Home

- Companies

- Zanni Group

- Products

- ZANNI - Filter Systems

ZANNI - Filter Systems

FromZanni Group

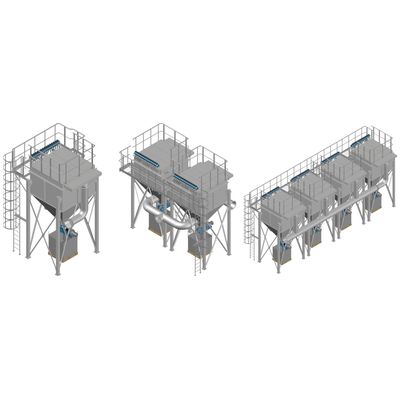

Our filter units are of modular design. Several modules can thus form a filter system. By default, these are made up of 1-2-3 and 4 modules and so on.

Most popular related searches

dry scrubbing system

electrostatic filter system

ceramic filter

filter cartridge

protective equipment

fabric filter

scrubbing system

rotary valve

pressure monitoring

washing system

- There are two ways to filter the exhaust gas.

- On the one hand there is the wet and dry washing technology and on the other hand the electrostatic filter technology.

- For our systems we mainly use the dry washing technology.

- For our dry washing technology we can offer ceramic filters and fabric filters.

- We prefer ceramic filters for the most of our furnaces, as these have a very high filter efficiency on the one hand and a very long service life on the other.

- Which of these both filter technologies is suitable is mainly a question of the amount of exhaust gas and the media itself.

Dry-washing systems

- Dry scrubbing systems are used to remove corrosive and toxic gases (for example SO2 and HCl) from the exhaust gas.

- They are very effective with low investment and operating costs.

- The temperature range for the dry-scrubbing solvent should be from 170°C up to 300°C.

- In this range the dry-scrubbing solvent can transfer the contents.

- Flue gas mixed with dry-scrubbing solvent create a layer on outside surface of the filter and accumulate during operation.

- The dust layer causes a pressure drop and a differential pressure measurement indicate necessary cleaning steps.

- At a certain differential pressure level the filter will be cleaned by pressure air with a reverse jet cleaning system which clean the filter by a jet impulse and the dust layer on the outside surface of the filter will fall down.

- At the bottom of the filter the ash feed by a rotary valve to a big bag or ash container.

Optional protective equipment against corrosion during plant shutdowns

- The insulation at the outside of filter body keeps it from corrosion, during shut down periods.

- The dust inside is contaminated with sulpher and other components.

- If the temperature falls below the dew point, corrosion could be happen.

- Therfor a standstill heater is additionally recommended to protect the housing from corrosion.

- This heater is only an option, because if it is necessary depends allways only on local conditions.

Easy replacement of the filter cartridges

- The filter can easily removed when necessary.

- It can be replaced by operation staff after training.