- Home

- Companies

- Apex Gasgen Limited

- Products

- Texol - Zero Air Generators

Texol - Zero Air Generators

The Zero Air uses new catalyst technology to produce hydrocarbon-free air with minimum power consumption and no moving parts. It is available in dual voltage, in both benchmount and 19" rackmount versions. Simply plug in the Zero Air generator and connect in-line to the application.

The Zero Air range is designed for constant use within laboratories and other applications. They operate by using catalytic combustion of hydrocarbons in a source of compressed air with minimum power consumption and no moving parts.

The range introduces no impedance to the compressed air supply. The models are vailable in both bench-mount and rack-mount versions and can be supplied with or without compressors.

Our range of low maintenance Zero Air Generators that offer flexibility and outputs of up to 40L/min.

- Hydrocarbon-free air to <0.1ppm

- New catalytic technology

- Low Power consumption

- Space saving

- Modular system

- Flows from 1 I/min to 80 I/min with no flow loss.

- Output Pressure to 147psi (10 Bar).

- GC-NPD

- GC-FPD

- GC-FID

- Emission Analyser

Utilising catalytic combust technology the Apex Zero Air series provides clean hydrocarbon free air for the most demanding of applications. Once connected to a compressed air source the system has no moving parts and will provide no restriction to the air flow through the system with a minimised power requirement. All the models in our range are small enough that they will easily sit on a workbench.

The Zero Air series provides flexibility to match your system requirements. We can customise the purity, flow rate and delivery pressure to suit your specifications.

- Flow Rates from 1 to 40 litres/min

- Output hydrocarbon content of <0.01 ppm

- Low Power requirement

- Rapid Start up

- Output Pressure up to 147 PSIg (10 Barg)

- Easy Installation

- Simple maintenance

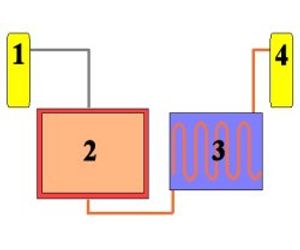

Compressed air enters the generator via a filter [1] that removes contaminants and bulk moisture via an integrated auto drain. The air then enters a heated chamber containing the catalytic converter [2] Here any hydrocarbons are burnt off and converted into trace amounts of carbon dioxide and water. The now hot, hydrocarbon free air passes through a cooler [3] were it is returned to ambient temperature before finally passing through another filter [4] and exiting the system.

- Flow rate (l/min): 1-40

- Purity: Total Hydrocarbon content < 0.1 ppm

- Dewpoint: -10

- Pressure (Barg/PSIg): From 1 / 14.7 to 10 / 147

- Start up time(mins): 3

- Voltage: 110-230VAC

- Height(mm): 303

- Width(mm): 9

- Depth(mm): 450

- Weight(Kg): 9-10