- Home

- Companies

- Jinan Zhongli Laser Equipment Co., Ltd.

- Products

- Zltech - Model ZL1390D - 1500watt, ...

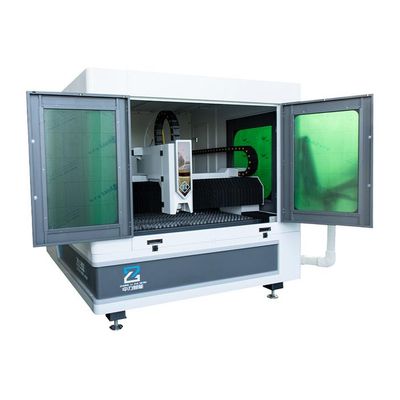

Zltech - Model ZL1390D -1500watt, 2000w, 3000watt High Precision Enclosed Laser Cutting Machine

The small 1390D CNC enclosed laser cutting machine is a kind of machine that uses a laser to cut metal materials. This kind of machine is mainly composed of a laser generator, a beam delivery system, a focusing lens, a worktable, a cooling system, a numerical control system, and other parts.

- Brand: ZLTECH

- Model: ZL1390D

- Category: Fiber Laser Cutting Machine

- Warranty: 2 Years

- Payment: TT, Visa, Mastercard, Credit Cards, Paypal

- Supply Ability: 200 Sets / Month

High efficiency 1390D enclosed fiber laser cutting machine’s working principle is that the laser generator’s laser beam is delivered through the beam delivery system and the focusing lens, and then focuses into a high-density laser beam. When the laser beam irradiates the surface of the workpiece, the workpiece is heated to its melting point or boiling point, and at the same time, the high-pressure gas coaxial with the laser beam blasts away the molten or vaporized metal. With the relative movement of the beam and the workpiece, the material is cut into a seam, thus achieving the cutting purpose.

Compared with traditional metal cutting processes, laser cutting technology has high precision, fast cutting speed, no limitation on cutting pattern, automatic layout to save material, smooth cutting edges, low processing cost, and other advantages. The enclosed laser cutting Machine adopts a non-contact cutting method, which will not damage the surface of the workpiece during the cutting process. The width of the cut seam is usually between 0.1mm and 0.3mm, and there is no mechanical stress on the cut surface. Precise numerical control programming achieves high-quality and efficient cutting results, which can also process arbitrary patterns. This kind of machine can complete the whole sheet processing without opening the mold, which is economical and time-saving.

- The laser cutting machine uses professional laser CNC software, supports various graphics and text, and can preview the cutting effect of the product. In addition, it is simple to operate and has a wide range of applications.

- The small closed laser cutting machine adopts an imported high-precision reducer, rack and pinion transmission, and dual-drive linear guide rail so that its positioning accuracy reaches within 0.05mm. In addition, its responsiveness ensures high-efficiency processing even when the processed materials are uneven.

- The small closed laser cutting machine is also equipped with a humanized automatic lubrication system, which can ensure the lubrication of guide rails, gears, and bearings nearly 500 times per minute, thereby reducing the friction of mechanical parts and improving the performance of the machine.

- The key core components of the laser cutting machine are all imported brands and come with a 2-year warranty and a service life of 100,000 hours without additional maintenance. In addition, it consumes 0.5-5 kilowatt hours of electricity per hour, which greatly reduces the cost of use.

- In general, small enclosed laser cutting machines have the advantages of high efficiency, high precision, low maintenance, and low investment. It can be applied to cutting various metal materials.

- Machine structure stable : Strong welded bed with high-temperature annealing

- Beam: Aviation grade tensile cast aluminum beam

- Laser Power: 1000W / 1500W / 2000W / 3000W/6000W / 8000W / 10000W and bigger

- Laser Source: Raycus / MAX / IPG / Reci

- Control System : Au3tech / FUSCUT / Weihong

- Cutting Head: Raytools / Au3tech / Ospri / Precitec

- Motor and Drivers: Japan Fuji / Yaskawa / Panasonic/Leadshine/Inovance

- Liner Guider System: Taiwan Hiwin

- Rail Thickness: X-axis: 25mm; Y-axis:30mm, Z-axis:20mm

- Transmit System: Dual Rack & Pinion type gear

- Rack: Taiwan YYC

- Reducer: Japan Shimpo / Japan Desbore