- Home

- Companies

- Zoom Petro Brand

- Products

- Zoom Petro - Predictable Oil Sludge ...

Zoom Petro - Predictable Oil Sludge Recovery Systems

There is money in oily waste. Our automated oil recovery system reclaims up to 99.7% of the contained hydrocarbons, turning waste into profit. You save money from minimized discharge costs and make money from valuable oil at the same time. Discover the technology behind the zero oil-waste system.

Oil waste comes in many forms, but it always causes trouble:

- Storage and disposal of hazardous oil waste causes substantial costs.

- The oil trapped inside the sludge cannot be sold and has to be written off.

This is where the Zoom Petro indirect thermal desorption unit (ITDU) comes in.

Specifically designed for the clean recovery of oil from sludge and oil-contaminated soil, Zoom Petro ITDU extracts close to 100% of contained hydrocarbons.

What`s more:

The separation process is fully automated and doesn`t require the addition of costly treatment chemicals or washing agents. Once set up, the system runs at full efficiency — literally at the press of a button.

The recovered oil is effectively free of impurities and can be sold as valuable product.

In other words: The Zoom Petro oily sludge recovery system pays for itself.

Our system not only recovers oily sludge, but also hard sludge deposits, bituminous residue, tar-balls, and tarcrete that are extremely difficult to treat using traditional technologies like soil washing and bioremediation.

This freedom in handling all kinds of oily sludge and other petroleum hydrocarbon (PHC) contamination, opens the door to a wide range of applications:

This soil remediation unit is suitable for the treatment of a wide range of oil sludge and more versatile than any other treatment method.

The following categories broadly describe the scope of applications:

Recovers drilling mud and other drilling waste

- Oil-based drilling mud (OBM)

- Synthetic-based drilling mud (SBM)

- Oil-based fluids (OBF)

- API separator bottom sediments

Recovers oily sludge from refineries and oil tanks

- Slop oils and tank bottoms from crude oil storage tanks, sedimentation tanks, and tank bottom pits.

- Oily waste and secondary oils from oil refineries, often stored in sludge lagoons, settling ponds, and sumps.

- Wet oil lakes (WOL)

- Other sludge pits, e.g., recovered oil from spills or leaks

Recovers oil-contaminated soils:

- Dry oil lakes (DOL)

- Oil-contaminated piles (OCPs) and oil-soaked soils

- Weathered crude, bituminous deposits, tar-balls, tarcrete and other high-viscosity hydrocarbons.

Developed at the Southwest Petroleum Institute specifically for use on the oilfield, our zero oil waste technology removes any uncertainty and turns your oil waste treatment project into a fast, robust, and predictable process.

In other words, your project will run on time, on spec, and on budget. No bad surprises anymore.

This achievement is thanks to the following core design principles:

The complete separation of oil waste into pure water, oil, and sediment is realized without having to add any treatment chemicals or proprietary washing agents.

This means:

- The effluent oil is free of chemical residues and can be readily sold.

- No dependence on the external supply of proprietary additives.

- Reliable separation even if the composition of feedstock material changes.

By not requiring any treatment chemicals, there won`t be any bad surprises. If it works in the lab, it works in the field.

The Zoom Petro technology reliably works in remote areas such as desert regions. This way, you can process all oil waste on-site, right where it is produced. No more costly transportation to a distant collection site.

These are the main reasons China Sinopec chose us as their partner:

This is one of the reasons why Sinopec, China`s largest oil supplier, choose us as their partner.

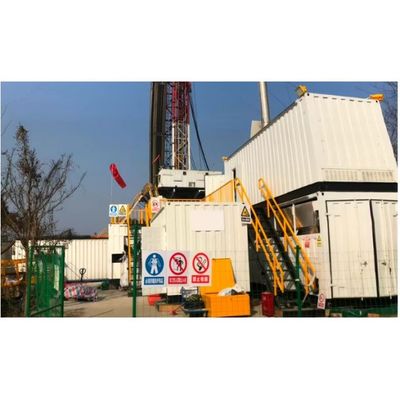

Due to its modularized design, the equipment can be mounted on any truck and is easily transported to even to the most remote locations.

No external power source is required. In distant locations, an additional generator, fueled with oil or gas, replaces the power grid.

In remote areas, operating a complicated system leads to complicated problems and costly downtime.

Not so with our oil waste treatment technology. Optimized for independent operation, the equipment runs reliably with minimal maintenance for long periods of time. This was made possible due to the following design decisions:

- A fully computerized cleaning process ensures stable operation at the press of a button.

- Simple, robust construction minimizes costly downtime

- No external power supply needed: The equipment runs on either oil or gas, generating the electricity it needs on-site.

When free space is hard to find, a Zoom Petro indirect thermal desorption unit still fits in. This means you can recover sludge, such as oil-based drilling fluid right at the source for reuse, without the hassle of having to transport the contaminant to a temporary dumping site first.

In the desert, water is a scarce resource. That`s why we decided to make saving water a priority:

- No water is added to the feedstock material. This is also true for solid matter from dry oil lakes and oil piles.

- No drop of water is lost. In fact, as the effluent water is of high purity (< 50 ppm oil residue), it is readily available for re-use without further filtration.

- Water used for cooling purposes is circulated in a closed-loop to minimize consumption.

The effluent oil, water, and inorganic solids returned by the Zoom Petro ITDU are of the highest purity, as you can see below.

In fact, the ability to cleanly separate oily sludge into its components is what makes this system so effective.

The high purity of the effluents gives the oil product a high market value, while the effluent water and sediment are classified non-toxic and can be safely reused to achieve zero landfill or waste disposal.

The following section describes the level of purity for each effluent in more detail.

Hydrocarbons

Containing only traces of water and solid particles, the hydrocarbons extracted from oil sludge and PHC contaminated soils using Zoom Petro ITDU are so pure that they can be safely reintroduced into the refinery process.

The Zoom Petro system is built around a technology called indirect thermal desorption (ITD).

An indirect thermal desorption unit (ITDU) applies heat from the outside to a nitrogen-blanketed chamber containing the oil-contaminated feedstock.

This thermal energy vaporizes the water and oil phase while fully preserving the quality of the hydrocarbons.

This separation process makes the recovery of oil waste highly predictable and cost-effective, especially when compared with other treatment technologies:

- No reliance on proprietary treatment chemicals ensures a consistent high quality of the effluent oil, water, and solids.

- Much purer effluents due to the system`s evaporation and distillation effect.

- No limitations in feedstock: Handles all kinds of oil waste, even hard sludge.

- Minimal water consumption, as feedstock is not mixed with water. Great for arid desert environments.

Broad Scope of Application

- Oil sludge from tank bottoms, sedimentation ponds, and oil lagoons

- Oil-based drilling mud (OBM) and oil-contaminated drilling waste

- Soil remediation (oil-laden soils)

- High-viscosity bituminous deposits

Cost Effective

- High throughput for shorter cleaning times.

- Reclaims up to 99.7% of hydrocarbons from the sludge or oil-based drill fluids.

- Non-toxic effluent sediment to achieve zero landfill or waste disposal.

- High-quality hydrocarbons reclaimed from oily waste can be sold old as valuable product.

Easy to Use

- Computerized oil recovery system at the "press of a button"

- No treatment chemicals ("washing agents") required

Remote-First Design

- Containerized module system for fast installation in remote areas.

- Simplified design with less moving parts for reduced maintenance costs.

- No dependence on proprietary treatment chemicals.

- Minimal water consumption to conserve this precious resource in arid environments.

Safe Operation

- Fully automatic operation minimizes points of failure

- Construction and installation to ATEX 114 (former ATEX 95)

- Operation in accordance with ATEX 137

Environmentally Friendly

- Toxic oil waste is turned to non-hazardous solids, oil, and water.

- Closed-loop cleaning system for near emission-free operation.

- All effluents leaving the system can be disposed of or reused without further treatment.

- No washing agents means the effluents won`t contain any chemical residues.