- Home

- Companies

- Applied Testing & Geosciences, LLC

- Services

- 3D Concrete Testing Service

3D Concrete Testing Service

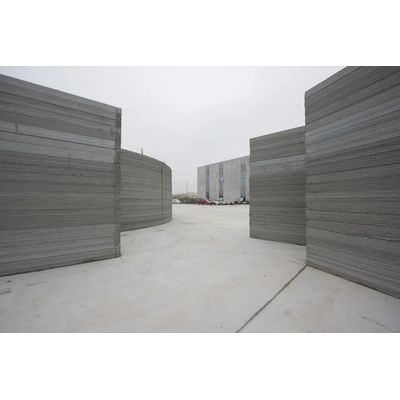

3D concrete printing is a process of using a 3D printer to create concrete structures. The printer uses a nozzle to deposit concrete in layers, which are then cured to form a solid structure. This process can be used to create a wide variety of concrete structures, including walls, columns, beams, and even entire buildings.

3D concrete printing offers a number of advantages over traditional construction methods. It is faster, more efficient, and can be used to create more complex structures. It is also more environmentally friendly, as it requires less material and produces less waste.

However, 3D concrete printing is still a relatively new technology, and there are some challenges that need to be addressed. One challenge is the cost of the printers. They are still very expensive, which limits their use to large-scale projects. Another challenge is the quality of the concrete. The concrete must be specially formulated to be 3D printable, and it can be difficult to achieve the same strength and durability as traditional concrete.

Despite these challenges, 3D concrete printing is a promising technology with the potential to revolutionize the construction industry. As the technology continues to develop, it is likely that 3D concrete printing will become more affordable and widespread.

Here are some of the benefits of using 3D concrete printing:

- Speed: 3D concrete printing can be much faster than traditional construction methods. For example, a 3D printer can print a wall in a matter of hours, while a traditional construction crew would take days or even weeks.

- Efficiency: 3D concrete printing is a very efficient use of materials. The printer only uses the amount of concrete that is needed, and there is very little waste.

- Versatility: 3D concrete printing can be used to create a wide variety of structures, including walls, columns, beams, and even entire buildings. It can also be used to create complex shapes and designs that would be difficult or impossible to create with traditional construction methods.

- Sustainability: 3D concrete printing is a more sustainable construction method than traditional methods. It requires less material and produces less waste.

Here are some of the challenges of using 3D concrete printing:

- Cost: The cost of 3D concrete printers is still relatively high, which limits their use to large-scale projects.

- Quality: The quality of 3D concrete is still being developed. It is important to use a high-quality concrete mix and to follow the proper printing procedures in order to achieve the desired strength and durability.

- Safety: 3D concrete printers can be large and complex machines, and they can pose a safety hazard if they are not operated properly.

Overall, 3D concrete printing is a promising technology with the potential to revolutionize the construction industry. As the technology continues to develop, it is likely that 3D concrete printing will become more affordable and widespread.

3D concrete testing is a process of evaluating the properties of concrete that has been printed using a 3D printer. This type of testing is important to ensure that the printed concrete meets the required strength, durability, and other performance criteria.

There are a variety of different 3D concrete testing methods that can be used. Some of the most common methods include:

- Compressive strength testing: This test measures the ability of the concrete to resist compression. It is one of the most important tests for evaluating the strength of concrete.

- Tensile strength testing: This test measures the ability of the concrete to resist tension. It is less common than compressive strength testing, but it can be important for evaluating the performance of concrete in certain applications, such as bridges and beams.

- Flexural strength testing: This test measures the ability of the concrete to resist bending. It is often used in conjunction with compressive strength testing to evaluate the overall performance of concrete.

- Water permeability testing: This test measures the ability of water to pass through the concrete. It is important for evaluating the durability of concrete, as water can cause corrosion and other damage.

- Abrasion testing: This test measures the ability of the concrete to resist wear and tear. It is important for evaluating the performance of concrete in applications where it will be exposed to abrasion, such as sidewalks and driveways.

3D concrete testing is an important part of ensuring the quality of concrete that has been printed using a 3D printer. By conducting regular testing, it is possible to identify any problems with the concrete and to take steps to correct them. This can help to ensure that the printed concrete meets the required strength, durability, and other performance criteria.

Here are some of the benefits of 3D concrete testing:

- Improved quality: 3D concrete testing can help to improve the quality of concrete by identifying any potential problems early on. This can help to prevent costly repairs or failures later on.

- Increased safety: 3D concrete testing can help to increase the safety of concrete structures by ensuring that they meet the required strength and durability standards.

- Reduced risk of accidents: 3D concrete testing can help to reduce the risk of accidents by identifying any potential hazards, such as weak spots in the concrete.

- Improved sustainability: 3D concrete testing can help to improve the sustainability of concrete structures by ensuring that they are designed and built to last.

Overall, 3D concrete testing is an important tool for ensuring the quality, safety, and sustainability of concrete structures.