- Home

- Companies

- Tridiagonal Solutions Inc

- Services

- Experimental Fluid Dynamics

Experimental Fluid Dynamics

A successful process development project will need to utilize both computational and experimental methods in a complimentary manner to accelerate the development process. Experimental studies either validate process solutions developed using computational models and/or provide input data,including boundary conditions or closure equations, required to build computational models.

Tridiagonal team recognizes the value experiments bring to solving flow enhancement and process development problems. Our expert EFD Solutions team is composed of Engineers and technicians with expertise in Design, Fabrication, Instrumentation and Control System Design.

This team is able to design and build customized test set ups and conduct experiments in a safe & reliable manner. Experiments to determine mal distribution in ducting networks, foaming and aeration during bottle filling operations, erosion in gas-solid flow lines, drying & roasting of food products andblending of fluids using static mixers in continuous processing applications are examples of some of our recent projects. These demonstrate the versatile nature of our projects and our team’s ability to design a range of experiments.

We are well equipped with appropriate infrastructure to support our experimental studies. Measurement techniques such as high speed photography, ultrasonic velocity profiler, conductivity based volume fraction sensor, high precision ultrasound thickness measurement system, hot wire anemometer are some of the instrumentation employed to capture data. A state of the art data acquisition and visualization system combined with web access to view experimentsenables our clients to feel close to their experiments.

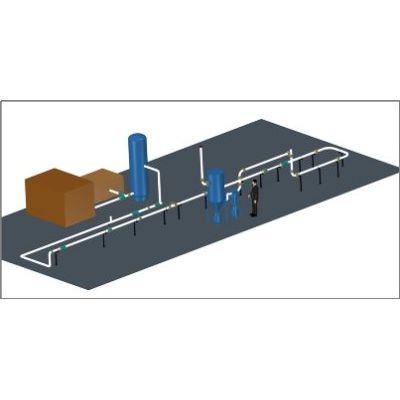

This team also specializes in designing and building lab and pilot scale process equipment. A key expertise at Tridiagonal is to design lab equipment that better mimic the mixing, heat or mass transfer limitation observed in the plant. This greatly reduces trials in the pilot and plant scale reactors and avoids the need to optimize recipes once the process has been transferred to production. Our clients are excited by the opportunity to reduce material wastages as well. These systems are skid mounted and come complete with data acquisition and control systems.

Tridiagonal operates a state of the art test facility to conduct erosion tests in gas-solid and gas-liquid-solid flows. The facility can achieve up to 45 m/s gas velocities in pipe sizes up to 6 inches. An in house developed sand injection system allows controlled injection of sand particles and sand fines for particle sizes ranging from 10 to 450 microns. High precision ultrasonic thickness gauge, also developed in house, is used to reliably measure wall thickness loss. Piping sections mimicking subsea and top side lay outs can be set up and analyzed for erosion. Recent projects have focused on erosion in sand fines, wet gas and undeveloped flows created by chokes or elbows in series.

Current focus of our EFD studies in non reacting single and multiphase flows with reacting flow capabilities in the works.