Flue Gas Purification Services

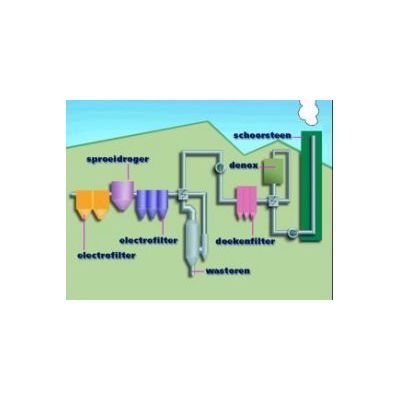

Incinerating waste creates flue gasses. These always contain various chemical substances – in the form of gasses or fine particles – in higher concentrations than are good for the environment. To prevent those from being released into the environment, the flue gasses are cleansed before they leave the chimney. This occurs by means of a so-called flue-gas purification system. At Twence, that system takes up about half the space in the waste-to-energy (WTE) incineration plant. The flue-gas purification system is made up of a number of components.

Upon leaving the combustion furnace with the boiler, the gasses – which at that point have a temperature of about 250° Celsius – are channelled through an electrostatic precipitator. This filter traps the larger particles, the so-called fly ash.In the case of a ‘wet’ treatment system like the ones we have in our existing two incineration lines, the flue-gasses then enter into a ‘scrubbing’ installation. This filters out primarily those substances that dissolve easily in water, such as sulphur dioxide (SO2, one of the culprits of acid rain) and hydrochloric acid (HCl). In the wet scrubber, the temperature of the gasses drops to about 60° Celsius. You could compare the effect of this wet scrubber to that of a water pipe.

After the wet scrubber comes the fabric filter, where a further cleansing takes place with the help of adsorbents (substances that can bond with other substances) such as active carbon (Norit), calcium or sodium bicarbonate (baking soda). The fine particles of dust are trapped here as well.

The following step is the deNOx system for filtering out nitrogen oxides. As this process requires a higher temperature, the gasses are heated to 240° Celsius. With the deNOx filter, nitrogen oxides are removed using ammonia as a catalyst to transform them into innocuous substances like steam and nitrogen. Following the deNOx treatment process, the gasses are blown out through the chimney with the help of a giant fan. At that point they are essentially free of any dangerous substances.

Dry scrubber

Although a wet scrubber works very well, it also has some disadvantages: the consumption of both water for scrubbing the gasses and energy (natural gas) for reheating them. European authorities are now paying more attention to the emissions from WTE incineration plants, but also to how those emissions are achieved, especially in terms of the catalysts used. Since a dry scrubber use no water (which for Twence would mean a savings of about 100,000 m3 per year) and requires considerably less energy for (re)heating the flue gasses, the modern dry scrubbers score better in that respect.

Another development is that the adsorbents used in the fabric filter have been greatly improved in recent years, which leads to better and better results. This makes it possible – also with a dry scrubber – to achieve emission figures that are far below the legal standard. Along with the lower energy-consumption in particular, this has led to the dry method being used more and more often in the newest plants. Twence has also chosen this type for its third incineration line, as well as for its biomass power plant.