- Home

- Companies

- Carolina Yarn and Fabrics, LLC

- Services

- Installation Services

Installation Services

Standard excavating, grading, and compaction equipment should be used to grade and compact the area to be protected and to excavate perimeter trenches

- Vegetation and obstructions, such as roots and projecting stones, should be removed

- Unsuitable soils should be removed and replaced with select materials and compacted according to contract specifications

- Draglines and bulldozers are suitable for rough grading, but fine grading shall be performed with a backhoe, grader, or similar equipment

- Underwater installation may be facilitated if a leveling course of granular material is placed prior to fabric form

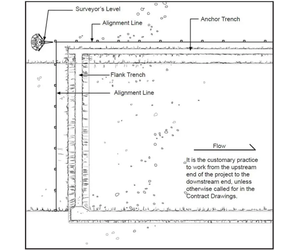

Establish Starting Point & Alignment Lines

- It is custom to work from upstream to downstream

- Prevents construction flows from undermining or bunching fabric

- String lines are set both parallel and perpendicular to the slope in an offset manner

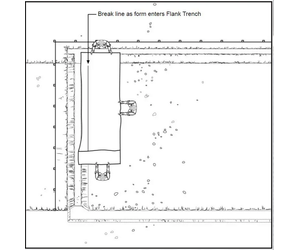

Placement of first fabric panel

- Panels are identified for placement according to fabrication drawings

- Panels are accordion folded and then rolled

- Panels should be extended into position by pulling the leading side of the panel

- Panels should be placed loosely, and extra form contraction should be gathered into temporary tucks at each seam and the top of the slope

Placement of remaining fabric panels

- If panels are sewn together in the field, the succeeding panel is placed atop the last mil width

- Panels are then joined together edge-to-edge by sewing the top layers and bottom layers independently

- If panels are joined together with pre-installed zippers, the succeeding panel is placed adjacent to the last mil width

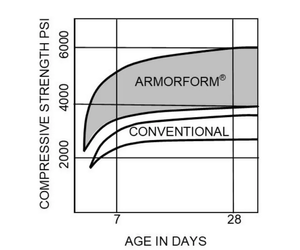

Fabric-formed fine aggregate concrete possesses superior physical properties. The compressive strength of fine aggregate concrete pumped into fabric forms is typically 1.5 to 1.75 times greater than companion samples taken from conventional concrete test cylinders. In addition, the fine aggregate concrete has less than 5% water absorption. This, combined with a "case-hardening" effect, produces a concrete that is abrasion resistant, durable under freeze-thaw action, resistant to "breakup caused by thermal cracking, highly impermeable, and resistant to acid, alkali salt, organic solvents, biological organisms and petrochemicals and permits FFC revetments to be constructed without reinforcement steel.

- Always maintain appropriate slack throughout the fabric to prevent fabric stretching, pinching, over-stressing, and non-uniform thicknesses

- Average pumping speed is 15 yd3/hour

- Standard pumping distance from worksite is 500 linear feet, with as much as 2,500 linear feet possible with sufficient pump(s) set-up

- Concrete line pumps are the choice pump for ease of installation. They are portable, towable, small, and can pump various mix designs. Boom trucks are NOT recommended

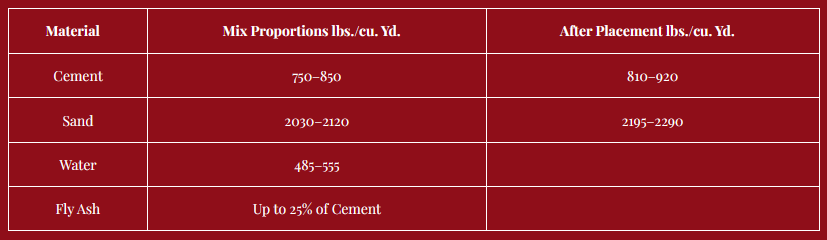

- Proper mix design is critical to a smooth, efficient, and successful installation

- Pumping procedures and sequence is key to preventing installation malfunctions

- Typical crew size includes four laborers, one pump operator, and one superintendent