- Home

- Companies

- CMC Klebetechnik GmbH

- Services

- Maintenance of ETFE Constructions ...

Maintenance of ETFE Constructions Services

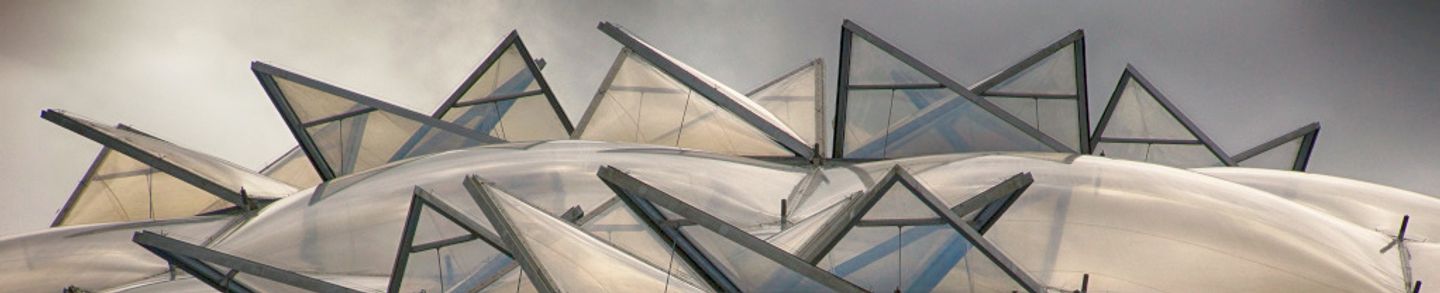

When it comes to light weight, great freedom of design and natural lighting, often an ETFE film is used. It has only about 1% of the weight of a glass surface and allows very graceful supporting structures. Repairing such constructions with ETFE tape significantly reduces service costs. The fluoroplastic ETFE has been exposed to natural and artificial weathering tests for more than 30 years. These films have proven that use over such a long time has no significant impact on usability. Another advantage of the films is that they are largely self-cleaning.

This means that air pollution, bird droppings or other debris will be washed off by the next rainfall. Elaborate roof maintenance systems for cleaning or overall high cleaning costs are not required.

ETFE films can be used in a wide temperature range and impress with their extremely good mechanical properties. In case of fire, the film retreats from the flame area and does not drip or burn. The weather resistance is excellent and the light transmission is depending on the film thickness at 95% or more. The passage of UV radiation is reduced only slightly, which is particularly interesting for greenhouses. Due to the great elasticity of the foil destruction by hailstorm is almost impossible.

As with all other sheet-like materials without adequate mechanical strength, ETFE films must also be shaped by means of bracing. This can be achieved by mechanical prestressing with high and low point formation, cable substructures or pneumatic prestressing. But then fascinating building facades or roof structures are possible, which are unparalleled because of their apparent lightness and design freedom.

Overall, fluoroplastic film roofs (membrane constructions) offer many advantages and can offer cost advantages of 30-50% over conventional, transparent canopy solutions.

Where there is light, there is shadow - ETFE repair tape

But in addition to all the positive qualities, there are also weak points. Normally ETFE membrane constructions are shaped and stabilized with dry air.

Especially on rooftops birds like to land. There they chop on your food to chop it up. The bigger the bird, the more energy they put into breaking up. Especially ETFE constructions near stadiums and other venues or near the coast suffer from this strain. Birds pick up leftover food or bring mussels and crabs to the roof to cut them into appropriate size. This can lead to small cracks and holes, through which the support air escapes. If there are sufficient numbers of membrane membrane failures, stability is compromised and energy costs for the air compressor increase too much.

Fortunately, the ETFE material has a low tear propagation. This allows minor damage to be repaired on-site without having to replace entire ETFE panels. For repair, companies that manufacture or maintain such membrane constructions use a transparent adhesive tape worldwide. It consists of a 100μm thick ETFE film, which is coated with an extremely weather-resistant adhesive. Thus, such openings can be permanently closed. The life of the adhesive tape is similar to the base film when properly bonded.

The ETFE adhesive tape can be upholstered in different widths or as a stamped part. Even colored or printed variants are available on request.

Even in the case of, for example, single-layered constructions, the largely invisible adhesive tape under supporting cables and guying can significantly contribute to protecting the main foil against abrasion. The ever-removable adhesive even makes it possible to replace the ETFE adhesive tape (maintenance, repair).

The CMC 77700 adhesive tape product can save a considerable amount of money by eliminating the need for time-consuming reloading on site or the replacement of entire membrane elements.