Metrological Support and Inspection Services

With over 20 years of experience in 3D metrology, control, inspection, calibration, on parts, assemblies, or subassemblies, and means of production, G2Metric provides you a total project management for all your on-site assembly and adjustment operations. We ensure the set-up of your facilities: from installation to final inspection, and receipt for production.

Because it is most important to control your product quality and to gather dimensional data to make you production processes reliable and to ensure your product conformity:

- Quality inspection (parts & products) or production control: serial inspection of parts, part inspection on machine, sub-assembly measurement, First Article Inspection…

- Measurement or adjustment on production line: part assembly assistance with metrology means, adjustment during production, survey inspection, raw part analysis and balancing…

We manage all types of inspections up to surface inspections and small characteristics thanks to our products:

- Dentcheck : measurement of Dent or bumps following impacts or deformations, measurement of pull-in

- GapGun : to check the conformity of your clearances (step) and misalignments (gap), other specific readings of small characteristics

- Gelsight : for the inspection of defects such as scratches or fixings

- HandyScan : for the inspection of small defects (eg: surface inspections, deformation, tulip effect on your bindings)

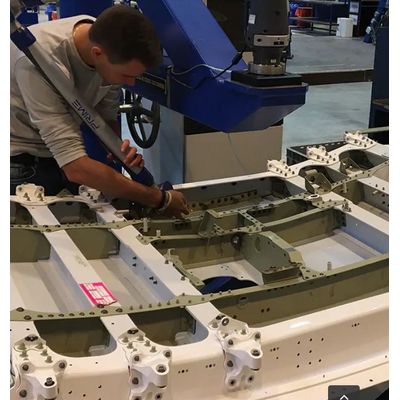

Because we understand that only a good and calibrated jig Production Line could produce good Part, we at G2Metric assist you adjusting and calibrating your Jigs & Tools.

- Workstation and complete assembly line erection and installation: adjustment, new equipment installation, transfer of single workstation and industrial transfer of complete production line, periodical inspection, repair and refurbishing

- Tool inspection and conformity checks: functional interfaces and surfaces inspection, mechanical adjustment, survey and anomaly inspection, periodical dimensional and functional inspection

Don’t forget that a Jig is moving along the Production time, annual periodical inspection is mandatory to ensure that it continue to provide Part as your requirements.