- Home

- Companies

- Akademi Cevre

- Services

- Precious Metal Refinery Services

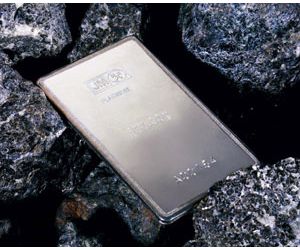

Precious Metal Refinery Services

The decomposition process with hydro or pyro methods from non-corrosive materials such as alloy, base metal, electrical electronic waste is called precious metal refinery process. The precious metals, which exist in electrical electronic goods and which are most precious, are gold, silver, platinum, palladium. The acquired gold and silver is mostly used in industrial area for handicrafts, jewellery and the production of hard money. Besides, precious metals those are in rare exotic metal class such as ruthenium, rhodium, osmium and iridium exist in e-waste goods. This kind of metals have been used as chemical catalyst for the last 20 years. After rare metals converted to fluidic state with pyrylosis method, precious metals are decomposed by solidification via molding and oxidation.

In hydrolysis method, the dissolution process of rare metals is done by including in the system acid or nitric acid, or hydrochloric acid with chlorine gas in aqua regia. During the process, some metals can diminish by interacting with salt, gas, nitro hydrate, etc.

The precious metals, which are decomposed respectively from metal calcination, crystallize again. Better results can be acquired by using catalysts containing precious metals.

- Rare metals:

- When they are heated to a high degree, they don’t undergo any structural change; they are not harmed by chemical factors.

- Example: Gold, platinum, silver, etc.

- Half-rare metal:

- They are not affected by room temperature and oxygen.

- -They oxidize in high temperature.

- Example: Mercury, tin, nickel, chrome, etc.

- Non-rare metals;

- They oxidize in humid weather in room temperature.

- Oxidation and rusting occur on the surface.

- Example: Iron, lead, zinc, etc.