- Home

- Companies

- Precognize

- Services

- Predictive Monitoring for Process ...

Predictive Monitoring for Process Plants

POTENTIAL PROBLEMS GET LOST ACROSS THE VAST PLANT; Process plants are enormous, complex organizations and any issue that arises can affect almost anything else. While these challenges could be simple for operation engineers to resolve when they begin, they are often only spotted once significant failures are caused, often requiring the plant to be shut down for repair. As a result, process engineers spend their time chasing fires instead of pursuing excellence.

PREDICTIVE MONITORING GIVES EARLY WARNING OF FAILURES

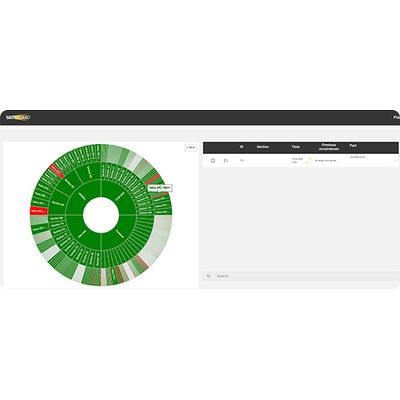

SAM GUARD Predictive Monitoring uses human-enhanced machine learning to model your entire plant and track data from every sensor. It identifies anomalies in the data to catch unexpected, non-repeating issues early, before they grow into serious and costly problems. With better insight into plant conditions you can optimize production, achieve operational excellence, and increase your bottom line.

A cement company gains over $3 million in revenue with predictive monitoring from SAM GUARD

A cement company implemented SAM GUARD in an analytical monitoring service to monitor and generate alerts across numerous plants run by the organization. With SAM GUARD’s help, one plant was able to reduce manufacturing costs by 10% and overtime by 50%, while another cut manufacturing costs by 6% and overtime by 65% annually.

By using SAM GUARD to reduce repair costs and slash plant downtime, the cement company gains $3,124,245 in revenue in the course of a single year.

SAM GUARD predictive monitoring is the only solution combining machine learning (AI) with human domain knowledge (HI) to monitor the entire plant, spotting unexpected, non-historic problems before they occur, no matter what the cause.

- Achieve operational excellence

- Detect unexpected & unforeseen events in advance

- Reduce production loss

- Increase plant uptime

- Save on part and machine replacement

- Enable process engineers to spend more time planning and less time chasing fires