- Home

- Companies

- TK Consult AG

- Services

- Rock Mechanics and Geomechanics

Rock Mechanics and Geomechanics

Our services include, but are not limited to:

Excavation/blasting damage zones around boreholes and tunnels:

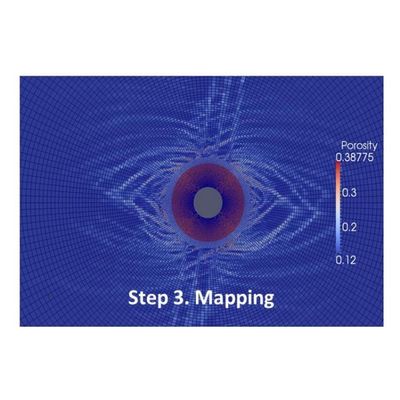

The excavation damage zone around wells, tunnels or shafts is a set of fractures caused by the excavation or blasting process. In tunnels, these fractures are preferential flow paths that may lead to local tunnel flooding. The situation is critical when the gallery is used as storage of radioactive or pernicious waste. In such case, fractures may represent a preferential migration path through which contaminants may access aquifers or the biosphere. As such, the excavation damage zone must be accurately characterized and, if possible, sealed. A scenario analysis mimicking different geological and operational conditions becomes crucial for the performance assesment and for the design of correction measures.

Analysis of well-logs and inference of geomechanical properties:

Well-logs are usually obtained after drilling. However, LWD (logging while drilling) techniques are on fashion nowadays because they allow the estimation of hydrogeomechanical properties and the stress state while drilling. This allows managers to take decisions almost in real time. Numerical modelling is well-suited to that end, as drilling or performance strategies can be easily updated as new information is available. LWD is often used to determine fracture density. This allows, amongst others, to change the trajectory of a water supply well to maximize the number of inflow points.

1D discrete fracture networks:

A key point in oil and gas or geothermal developments is often the degree of connectivity between the borehole and the formation. To address this problem, we have developed a flexible workflow to model the hydraulic connectivity of the borehole near-field. Different completion systems can be tested, e.g., cement, plug-and-perf, etc. Fracture families are generated stochastically. Thus, the output is not just one single best connectivity, but a histogram including all tested possibilities.