- Home

- Companies

- Dongguan Luphi Electronics Technology ...

- Services

- Structure Design Service

Structure Design Service

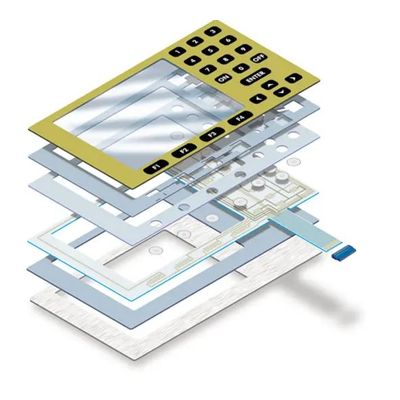

User interface products structure design refers to the planning and design activities of the possible components and construction methods during the product design process. The purpose of structural design is to determine the overall structure of a user interface module product and define the relationships between the various components of the module, while considering the matching with the client`s host device, in order to achieve the functional and performance requirements of the user interface module.

LuphiTouch® has a team of experienced product structure design engineers who can quickly design a reasonable product structure based on the requirements of the client`s user interface product. During the structure design process, the structural engineers will communicate closely with our electronic engineers to avoid design defects that may affect the product`s functionality in the later stages. We can develop various plastic, metal, and silicone structures for the client`s interface module products.

- This is the base layer that provides structural support and insulation.

- Common materials used include polyester (PET), polycarbonate (PC), or polyimide (PI) films.

- The substrate layer should have good mechanical and electrical properties.

- These layers contain the conductive circuits and traces that enable the switch functionality.

- Commonly used materials include silver, copper, or conductive inks/coatings.

- The conductive layers are typically printed or etched onto the substrate layer.

- This layer is used to separate and isolate the conductive layers.

- It prevents short circuits and ensures proper electrical isolation.

- Materials like polyester, polyimide, or acrylics are commonly used for the insulation layer.

- The spacer layer creates a gap between the conductive layers when the switch is not activated.

- It is made of a non-conductive material, such as polyester or polyimide.

- The thickness of the spacer layer determines the actuation force required to press the switch.

- The graphic overlay is the top-most layer that provides the visual design and labeling.

- It can be printed with graphics, icons, or text to indicate the switch functions.

- The overlay is typically made of polyester or polycarbonate material.

- Adhesive layers are used to bond the various layers together, creating a cohesive structure.

- Pressure-sensitive adhesives (PSA) or heat-activated adhesives are commonly used.

- The adhesive layers must be carefully selected to ensure proper bonding and durability.

- Membrane switches may include additional sealing or encapsulation layers to protect the internal components.

- These layers can provide water resistance, dust protection, and environmental shielding.

- Materials like silicone, polyurethane, or epoxy resins are often used for this purpose.

- The overall structure design of membrane switches aims to achieve a durable, reliable, and cost-effective solution.