- Home

- Companies

- Wayken Rapid Manufacturing Limited

- Services

- Vacuum Casting Services

Vacuum Casting Services

- Low cost for silicone molds

Cast urethane parts are made of cheap molds, eliminating the need to invest in expensive and time-consuming metal tooling. It is a cost effective method for making high quality prototypes and low volumes of parts. - Fast delivery

Up to 50 functional cast urethane parts can be produced in 10 to 15 days when you choose vacuum casting. - A wide selection of materials

Casting resins materials range from soft and flexible to rigid and impact-resistant, as well as colored and clear. - High precision and fine details

Vacuum casting provides end-use parts of high precision and fine details with production-level quality. - Excellent surface finish

Urethane casting can provide better surface textures compared with CNC prototyping or 3D printing.

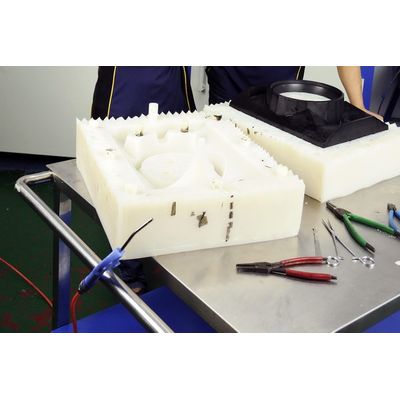

The vacuum casting process has three steps: master pattern, molding, and casting.

The quality of the casting urethane parts is determined by the quality of the master pattern, which is best machined by CNC when you need to hold tight tolerance, glossy finish, or even optically clear. In addition, we also will consider making the master by SLA for those parts with more complex shapes and structures.

We can paint parts surface for texture or satin effect to simulate the final mold texture of the product. The silicone molds will copy the details and textures from the original master, so the cast urethane parts will come out the same as the master model without any extra finish on the surface.

- Paste tape in a flat position around the master, so that it is easy to open the mold later, which will also become the parting surface of the final mold.

- The master model is suspended in a casting box and placed with plastic rods to set gates and vents.

- Liquid silicone is poured around the master and removal all air, creating a vacuum chamber to ensure the master mold is free of air bubbles. Then is cured liquid material in an oven, at a temperature of 40?. It generally takes 8-16 hours depending on the volume of the mold.

- Once the silicone rubber is cured, cut open the casting box, remove the master model from the silicone to form an empty cavity, and the silicone mold is made.

- First, put the silicone mold into the oven and preheat it to 60-70°C.

- It is very important to choose a suitable release agent before closing the mold and use it correctly to avoid stickiness and surface defects.

- Prepare the polyurethane resins to preheat them to about 40°C before use. Mix two-component casting resins in exact proportions, and then fully stir and degas for 50-60 seconds under vacuum to avoid air pockets or bubbles

- The resin is poured into the mold inside the vacuum chamber under computer control and cured again in the oven. Average cure time: 1-3 hours for small parts and 3-6 hours for big parts.

- Remove the casting part from the silicone mold after curing. Prepare to repeat this vacuum casting work cycle.

Standard tolerance on ±0.15mm/100mm, with the highest precision able to reach ±0.05 mm.

The vacuum equipment can hold 2.0M*1.2M*1.0M mold specifications.

The minimum wall thickness is 0.5mm, the best is 1.5mm~2.5mm to ensure the mold is filled properly.

Typical quantities up to 20-25 copies per mold. If the part requires high quality such as clear or complex structures, in typical quantities one mold can only make 12 or even 10 casting parts.

Up to 50 copies can be produced in 7 to 10 days, depending on the mold’s complexity and volumes.

Colored, textured, painted, coated, clear polished, insert, and over-molding.