- Home

- Companies

- Wahaso - Water Harvesting Solutions, ...

- Services

- Wahaso - Commercial Systems for Onsite ...

Wahaso - Commercial Systems for Onsite Water Reuse (Harvesting)

Commercial buildings can save millions of gallons of potable water each year by harvesting rainwater, grey water, condensate and other on-site sources for non-potable uses like toilet flushing, irrigation and cooling tower make-up. Wahaso provides complete design/build systems custom-tailored to each building. Rainwater harvesting is the most common system type, and Wahaso specializes in commercial rainwater harvesting systems. Unlike the more simple systems installed by homeowners, our rainwater harvesting systems are designed with the commercial-grade components and sophisticated controls required in commercial buildings for reliability, automated functions and connectivity to BAS systems.

The most important advantage of greywater over rainwater for harvesting is that in a residential building - where there are lots of uses of showers and sinks - the greywater provides a constant supply of harvested water for flushing toilets. Our experience is that the greywater supply can usually meet 100% of toilet flushing requirements. And because the supply is steady and predictable, (unlike rainwater!), the storage requirements are dramatically less, saving storage space and costs.

Harvesting greywater is a relatively new practice in commercial and institutional buildings, and carries many system and regulatory implications not associated with rainwater or condensate harvesting. Unlike other renewable water sources, greywater normally contains biological and chemical contaminants that can quickly turn to "black water", resulting in unpleasant odors, colors and health hazards if not treated correctly.

Water Harvesting Solutions utilizes a number of leading-edge filtration, sterilization and monitoring steps to bring the water to near-potable quality that is able to eliminate any health and aesthetic concerns while meeting the regulatory requirements of most communities.

It is important to note that the term "greywater" refers to untreated water from showers and sinks. Once the greywater has been filtered and sanitized - its classification changes from "greywater" to "on site treated non-potable water" and it is then safe to store and utilize for many purposes.

The following section provides a general overview of the system components of a commercial greywater harvesting system from Wahaso.

Greywater is routed from showers, baths and sinks through a plumbing system that is separate from toilets and urinals – which produce black water. Greywater should be treated almost immediately to stabilize it and prevent it from going septic. Untreated greywater should never be stored more than a few hours.

- The first filtration step is designed to quickly remove the larger particulates inherent in shower and sink discharges. This is accomplished with a settling tank or with a large mesh screen or bag filter.

- For commercial systems, the next filtration stage uses a multi-media filter that removes all particulates greater than 5 microns in size. The filter minimizes maintanance by automatically going through a backwash step that flushes debris to the sewer system and the resets the multiple levels of filtration media.

- Wahaso`s greywater system also injects liquid chlorine into the greywater stream to immediately kill pathogens that could create odors and foul the filtration system.

It is necessary to sterilize the water to keep algae, viruses, bacteria and other organic contaminants from forming in the storage tanks. There are several technologies available for this purpose.

Chlorination. Because of the higher contaminants inherent in greywater, residual sterilization capacity is valuable in keeping the entire system clean. Chlorine sterilization is the most common method to achieve this. For Wahaso projects, we prefer chlorination using calcium hypochlorite in the form of solid briquettes. The chemical is similar to that used in a municipal water treatment systems but is in a form that is safer and easier for building maintenance staff to handle.

Hypochlorite briquettes are added to a hopper in the dosing unit where they are combined with water to make a high concentration chlorine liquid. An automatic free chlorine analyzer continuously monitors the parts per million (ppm) level and proportionally controls a chemical injection pump to dose in more chlorine as necessary to maintain the preset level.

Other sterilizing agents that can be used include Ozone and Chlorine Dioxide. These sterilizing agents are very powerful and are typically only used on greywater systems. They are more hazardous to handle and require on-site generation of the Ozone or Chlorine Dioxide gas plus an injection system.

Some greywater systems use ultraviolet sterilizers that expose the water to a specific wavelength of UV light that destroys the DNA of organisms present and keeps the water sterile. Sizing of the UV system is critical to maintain sufficient exposure rates to keep the water sterile. The advantages of UV sterilization are that it uses no chemicals to kill pathogens, requires minimal maintenance and is significantly less expensive than chlorination systems. It`s biggest disadvantage is that the UV light can only kill pathogens that are directly exposed to the tubes - and there is no residual killing capability like chlorine. That can lead to fouling of filters and growth of bacteria in other parts of the system.

Storage of the treated greywater is determined by the demand and uses for the water, available greywater volume and turnover frequency, and space to locate the tanks. For more information on the options for storing rainwater and greywater, see our Water Storage page.

All storage systems have a connection to a municipal source so that toilet flushing can occur even if there is not an adequate supply source of greywater. An air gap inlet can automatically be turned on to make-up water in the treated tank should a supply problem develop in the greywater harvesting system. In typical applications of a greywater system for toilet flushing, there is more than enough supply of greywater from showers and baths to meet flushing requirements.

Wahaso tank systems can be pre-mounted on skids for ease of installation with all internal piping manifolds and sensors mounted and pre-tested at our fabrication center. All of our tanks are NSF-61 rated for potable water even though we are not using this water for drinking purposes.

Larger underground storage tanks are usually considered when the system also incorporates rainwater from roofs and parking lots. These systems are typically only considered for water intended for irrigation.

A repressurization system is required to move the rainwater to toilets or other applications throughout the building. In commercial systems, pump skids are duplex, with two identical commercial grade pumps in tandem with each rated at 70% of peak demand. The operating system alternates demand between the two pumps; if a high demand situation occurs, both pumps can be made available. And if one pump should fail, the system will continue to provide harvested water.

We work closely with building engineers to properly size the pumps so that adequate pressure (PSI) and volume (GPM) is available at the farthest - and highest altitude - end point in the system.

Water Harvesting Solutions employs programmable logic controllers (Allen-Bradley as standard) that fully automate and control the entire process for greywater harvesting. Our proprietary software is customized for each application and provides the capability of interfacing with building automatic systems and other alarm and condition monitoring.

In addition to monitoring the system mechanicals, the control system can track the amount of water in each tank and track and display the monthly amount of water harvested. An interface allows remote monitoring via a web page for maintenance or educational purposes. Wahaso can use the remote access to help a building maintenance staff diagnose potential system problems.

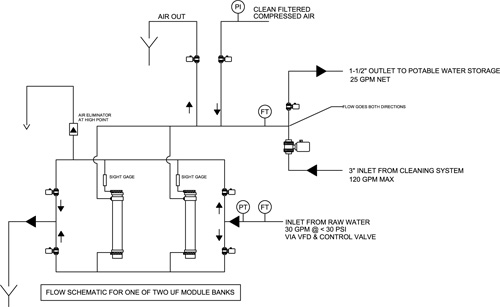

Wahaso uses a proprietary ultra filtration system for processing greywater from showers and sinks. We believe that ultra filtration offers significant advantages over conventional water treatment methods.

Sand filtration was considered to be the state-of-the-art method in the world of water treatment for many hundreds of years. Similar to natural water cycles in which water flows through layers of rock and sand, this method involves trickling the water through beds of sand in order to clean it. It was truly a revolution in its time and continues to be the principal method of water filtration in many communities.

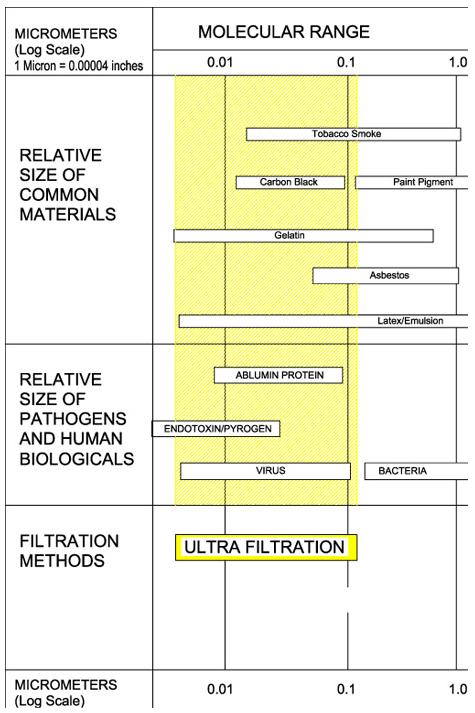

Sand filtration has some distinct disadvantages. Just because water is clear, it is not necessarily free of contaminants that could be harmful. Sand filtration is typically effective to a filtration level of around 10 microns (see filtration chart following). Pathogens, bacteria, and viruses can break through sand and particle filtration into the filtered water supply. Also, as the sand traps particles, a “filter cake” forms on the top of the sand, making it less efficient and reducing the quality of filtration. Back washing the sand restores the filter’s quality, but this frequent step wastes a significant amount of filtered water – as much as 25% is sent to the sanitary sewer.

Ultra Filtration Membrane Technology offers a significant advance in filtration technology. There are now numerous applications where ultra filtration can replace or effectively supplement sand filtration. Ultra Filtration achieves better results in filtering out pathogens, is more efficient in total clean water produced, takes up significantly less space, and is renowned for being easy to manage and simple to integrate into complex water treatment systems. Ultra Filtration will effectively filter out pathogens, viruses, and bacteria to 0.02 microns or better. When combined with chlorine pre-treatment, Ultra Filtration will provide pathogen free water.

An important advantage of Ultra Filtration is its ability to deliver clean water regardless of the system load; the filtered water will always maintain the same high level of quality and purity. Sand filtration simply cannot match this result.

Wahaso`s greywater harvesting systems are engineered to meet the rigors of commercial and institutional use. Our Ultra Filtration Systems are designed for fully automatic operation. Wahaso provides a PLC-based control system that monitors the process and automates the various operating modes of the ultra filtration process: filtration, cleaning, and back washing.