- Home

- Companies

- Snic Solutions

- Software

- Snic Solutions - Version Opcenter APS - ...

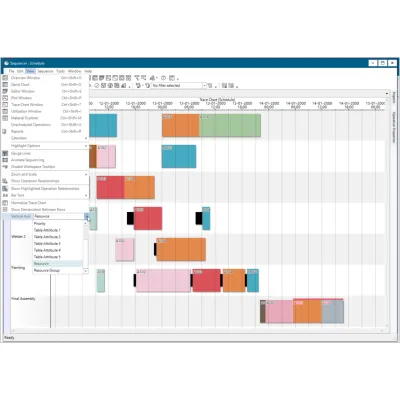

Snic Solutions - Version Opcenter APS -Advanced Planning and Scheduling (APS) Tool

Opcenter APS is an advanced planning and scheduling (APS) tool designed to refine manufacturing operations. It enhances production efficiency through sophisticated algorithms and data analytics, producing optimized schedules that consider machine, material, and labor constraints.

Opcenter APS integrates data from various systems, including enterprise resource planning (ERP), manufacturing execution systems (MES), and direct shop floor inputs.

This comprehensive data collection is analyzed to develop a precise production schedule, optimizing the balance between costs, lead time, times, and resource utilization.

The software's powerful algorithms provide a strategic overview, allowing for cost minimization and enhanced efficiency, while its real-time tracking capabilities enable ongoing adjustments to keep production aligned with goals.

Medium-term Tactical Planning

Reduces manual tasks by automating the sequence of operations for samples and tests.

Long-term Strategic Planning

Plan production months and years in advance, ensuring alignment with future demand projections.

Inventory Management

Reduce waste, identify potential shortages, and optimize the flow of raw materials throughout the production cycle.

Detailed Sequencing and Scheduling

Enhances production by planning and scheduling tasks, reducing idle time and maximizing resource utilization.

Productivity Improvements

Pinpoints and alleviates bottlenecks, shortens setup times, and optimizes machinery use, resulting in increased productivity and lower operational costs.

On-time Delivery

Meet customer demands more effectively while reducing lead times by enhancing availability and efficiency in production processes