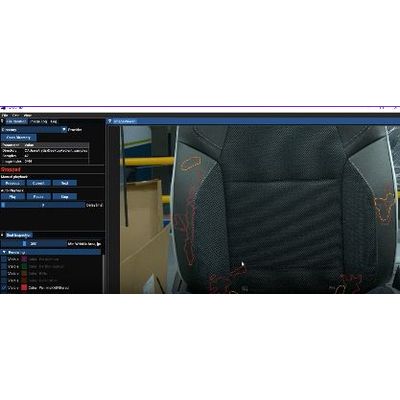

EasyODM - AI-Driven Seats Quality Control Software

The EasyODM AI-Driven Seats Quality Control System is an advanced machine vision software designed for precise defect detection in seat manufacturing. By integrating seamlessly into existing production lines, this software enhances the inspection process with minimal disruption. It utilizes industrial cameras for high-resolution image capture, extracting relevant features like grain patterns, color, texture, and surface anomalies. Equipped with self-improving AI algorithms, the system delivers real-time defect identification, ensuring every seat meets predefined standards. This includes detecting material flaws, ergonomic inconsistencies, and structural issues, such as weak joints or improper frame alignment. The system offers significant cost savings, achieving up to 30 times reduction in operational expenses and delivering a 99% accuracy rate in detecting defects like wrinkles.

Inline seats inspection propels your production quality and efficiency, giving you the upper hand in a competitive market.

EasyODM software integrates into your existing production line, enhancing seat inspection with minimal disruption and maximizing quality control efficiency.

Utilizes industrial cameras to capture high-resolution images of various seats.

Extract relevant characteristics such as grain pattern, color, texture, and surface anomalies from the images.

Employs machine learning to compare against quality benchmarks and detect anomalies.

Pinpoints defects in real-time, from material flaws to ergonomic inconsistencies, ensuring every seat meets the set standards.

Our system can accurately identify ISOFIX plastic parts, buttons, and handles, ensuring comprehensive quality control with our pattern correlation-based algorithm all in one software. Everything is done with the same cameras and you don’t need additional sensors to do that.

- High Precision: Detects specific elements like ISOFIX points with high accuracy;

- Adaptability: Suitable for various contexts, including labels, prints, and other plastic elements;

- Customizable: Specific areas can be marked for detection;

Experience the future of seats quality control with EasyODM’s AI-driven technology—where no defect goes unnoticed.