- Home

- Companies

- Robacks Sweden AB

- Software

- RCS - Version Linux 4 - Concrete ...

RCS - Version Linux 4 -Concrete Production Control System

Includes everything needed for an effective and safe concrete production . Process control with graphical and text-based representation of the process of progress. SS-EN206-2 Adapted to the norm EN206 with managing exposure class, consistency classes and alarm for sampling a concrete family. Recipe Calculate Automatic calculation of the VCT / VBT, finhaltsjustering mm. Recipe correction corrects the formula for moisture in materials, additive recipe, silikainblandning.

- Recipe A simple way to administer the recipes. Basic recipe, adding recipes and for advanced - combining recipes.

- Washing program Adjust the next weighing with respect to the washing materials are in the mixer.

- Multi-mixer Manage multiple mixers simultaneously

- Multi-dose Always a load on time. In the car, in the mixers, the scales, the locking shoe.

- Optimizing production capacity when the system always ensures that all instruments are charged for the next batch.

- Quick overview of progress with the graphic presentation of plant

- Directories Keep track of customers with work records.

- Order processing Place orders in advance by time. The orders are displayed only when it`s time to mix.

- Print Management Printing of delivery notes, records and statistics.

- Logging of events, mixing data, etc. The file or printer.

- Simulation Test a new recipe or a new setting before a live production with the unique simulation function.

- Compile the statistics based on the basic data which customers, recipes, materials, etc.

- Control hoisting of material directly in the system as an integral part of the process.

- Help menus All registers accessible through quick search and help functions.

- Network RCS-Linux is designed for networking with the latest hardware and softwares.

- Remote Support Standard remote control software available - VNC.

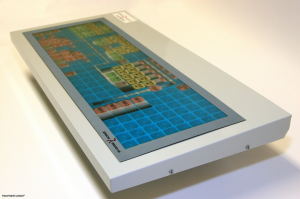

Röbäck console enables manual handling of proscessen buttons, 192 pieces, are disposed in a matrix (8 x 24 pieces)

Encapsulated in a robust metal housing and replaceable layout.

Easy to add new features. Available keys are assigned new functions in the PLC code.

- Ethernet-based communications interface

- RS232 and USB - interface

- Can be deployed in factory via network

- Flexibility to add more buttons and functions.

- Several tables can be linked together for more advanced factories

- Push buttons with tightness.

- LED indicator on the button to give indication back.

- Extra-bright LEDs provide a good indication even in daylight.

- Interchangeable graphic layout.

RCS WEB

- For your need for statistics on the entire network access to the RCS WEB

- It takes you easily produce statistics on customers, deliveries, etc.

Integration

- RCS has an open database and can be easily integrated with your other systems such as finance and lab / testing.

Stability

- Linux is a recognized stable operating system that is used in systems where stability and security is a requirement. Used for many of the big web and e-mail servers on the Internet, as well as industrial applications.

- Linux has excellent support for networking, modern hardware, redundant systems (RAID), database communication, etc.

- RCS-Linux creates a technical platform available and developed for the future and is both flexible and future-proof.

Security

- Although the process computer is connected to the network`s integrity from intrusion and virus excellent.

- Partly because it spreads very few viruses for Linux, and secondly there is an advanced network management that effectively prevents any attempt to attack the computer.