- Home

- Companies

- UREASON International BV

- Software

- Condition Based Maintenance Software

Condition Based Maintenance Software

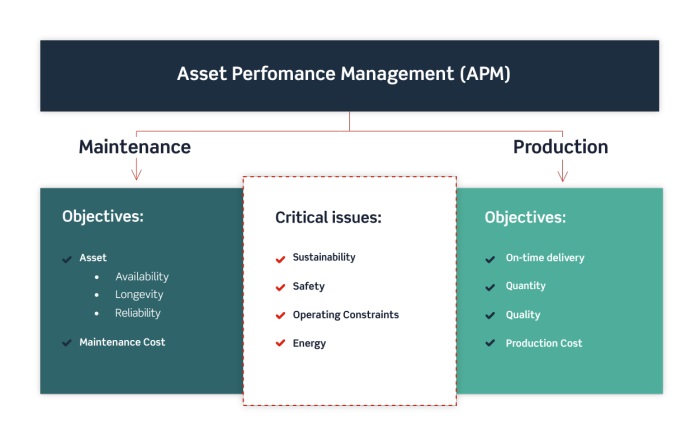

UReason’s APM software offers you the possibility to use Condition Based Maintenance to ensure asset reliability, worker safety, costs reductions, and high asset performance – without the need to interrupt equipment processes.

Condition Based Maintenance is one of the most important product technologies used by UReason APM software to ensure, among others, high asset performance. Such maintenance uses the data of an asset to determine its usage and actual status. On the basis of the asset data performance decrease, upcoming asset failure can be determined and certain trends can be identified.

Benefits of Condition Based Maintenance:

- It has the ability to operate while assets are in use, thus without interrupting any of the equipment processes;

- Compared to Preventive Maintenance, Condition Based Maintenance ensures asset reliability, worker safety, and costs reductions since the maintenance activities are scheduled whenever the performance of the asset decreases accordingly.

Maintenance costs are a major part of the total operating costs of all manufacturing plants. The challenge our customers face is maximising the return on capital assets. UReason APM software helps you improve the reliability and availability of production assets while minimising the risk and operating costs.

We have many years of experience in Asset Performance Management (APM). We use the valuable asset and process data that is available in your historical data archives and combine it with the maintenance data available in CMMS systems to provide you with insights in how well your assets are performing.