- Home

- Companies

- Acceleware Ltd

- Software

- EM Powered Heat for Heavy Oil - Version ...

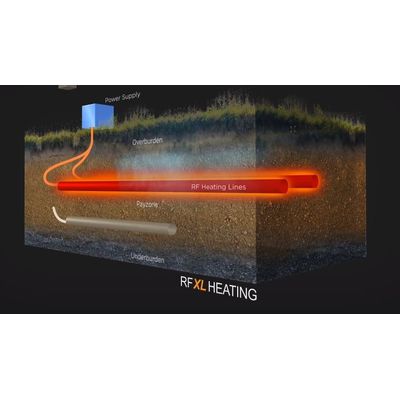

EM Powered Heat for Heavy Oil - Version RF XL -Decarbonizing Heavy Oil and Oil Sands

RF XL can be implemented as an expansion to an existing SAGD project, allowing operators to increase production while reducing their emissions intensity. RF XL can also be implemented as a new greenfield project, where it can eliminate the requirement for steam plants and fresh water. The RF XL technology is simple and quick to deploy, allowing heavy oil operators to compete with short cycle resource development such as light tight oil multi-stage frac plays. Global heavy oil deposits represent an addressable market of over 8 trillion barrels of oil.

Acceleware believes that our RF XL process can be fully commercialized and available on the market by 2023.

The RF XL process uses RF energy to generate heat, which converts the water already existing within the oil sands reservoir to steam, mobilizing the bitumen and allowing it to flow to the producing well. Acceleware's RF XL process, coupled with new software advancements, involves the drilling of two RF heating lines into the target zone and their connection to a surface power supply. RF XL does not require the injection of steam into the target zone, eliminating the need for water source wells, water treatment equipment, and steam generators, as well as the requirement for costly chemicals or solvents. In addition to the obvious OPEX and CAPEX savings, RF XL can immediately reduce GHG emissions compared to SAGD or other steam-based heavy oil or bitumen extraction processes.

For more details, download our white paper, "How RF XL can Profitably Produce Oil Sands and Heavy Oil with Low Environmental Impacts"

Acceleware`s RF XL delivers energy to in-situ oil more effectively than any existing thermal process, including SAGD, at a lower cost and with lower emissions. As a result, operators are able to produce oil cleanly and profitably from a wider range of reservoir types than ever before. The most GHG-intensive components of traditional oil sands projects are the treatment of water and the generation of steam at the surface. Generating and delivering one unit of electromagnetic heat requires far less energy than an equivalent amount of steam heat.

As a water molecule in the reservoir turns to steam, it no longer absorbs energy produced by the RF XL process, enabling the energy to permeate further throughout the rock formation, creating more steam and mobilizing more oil. This `volumetric heating` effect improves the efficiency of the process as it takes less energy to heat the reservoir with RF XL than with SAGD. Since the heat and steam are generated within the reservoir, there is no loss of heat or energy from surface to reservoir.

We also expect that the RF XL technology will allow us to achieve first oil from a development project significantly faster than SAGD or other enhanced oil recovery techniques owing to reduced surface infrastructure construction, and more efficient heating and production mechanics.