To ensure the success of drilling operations, it is critical to select the right bit for the right application.

Drill bit selection is a complex process, as a lot of variables need to be accounted for: lithology, trajectory, borehole assembly, length of the interval to drill, drilling mud, rig specification and limitations, bit design features, and properties.

This makes bit design selection a time-consuming, highly specialized, and often subjective exercise.

High specification bits are expensive and when incorrectly selected will not deliver the desired performance. This makes PDC bits mostly prohibitive in budget-sensitive but challenging applications, like geothermal drilling.

ZerdaLab is reducing the cost of high specification drill bits while improving the speed and quality of bit selection for the customer’s application.

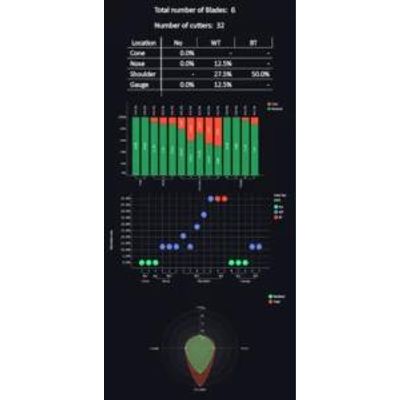

- ML Enabled dull grading

- Automated, objective, accurate and comprehensive dullgrade report

- Automated performance trend analysis

- Bit dull-based dysfunction prediction

- Recommendations based on bit dull sequencing and characteristics