- Home

- Companies

- Senitron Corporation

- Software

- Senitron - Enterprise Resource Control ...

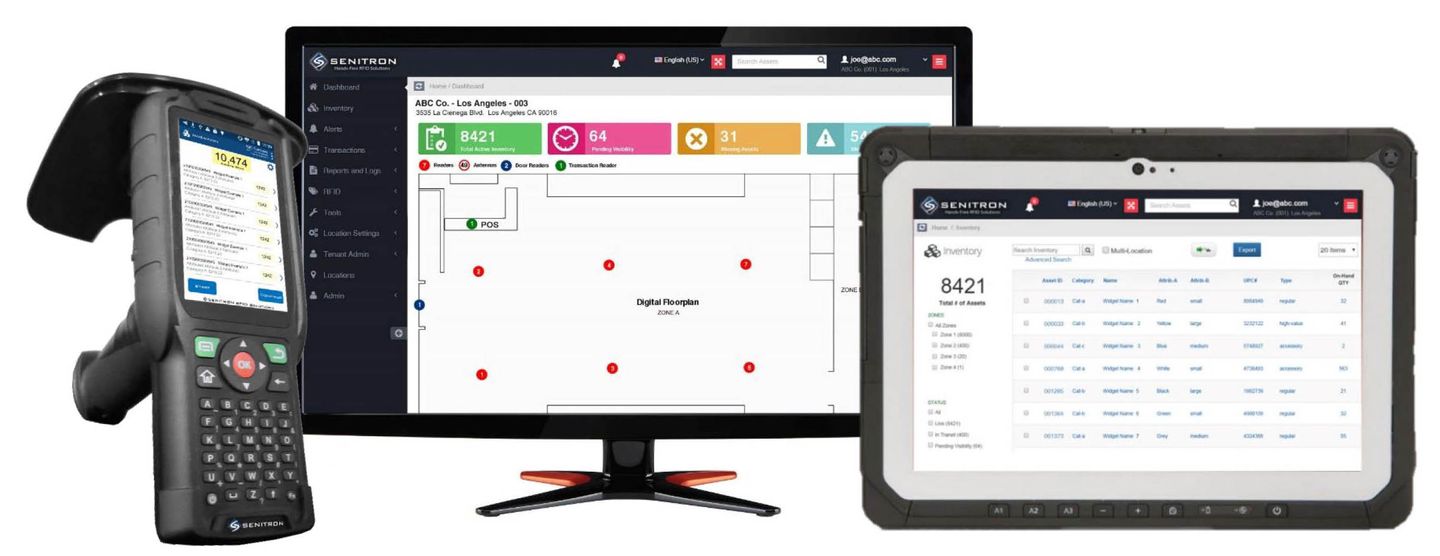

Senitron - Enterprise Resource Control (ERC) Software

Enterprise Resource Control (ERC) is a revolutionary system specifically designed for manufacturing and warehousing to take control of inventory accuracy and all aspects of operations. ERC combines (RFID) real-time asset tracking technology with proprietary cutting-edge software, creating an all-in-one solution to transact, monitor, and driveactivities and business decisions in real-time.

Who Needs ERC?

Manufacturing or distribution that are struggling with inventory accuracy, excess & obsolescence and on-time delivery. A company that is looking to improve contribution margins, productivity, labor efficiency, material usage variance and shop floor communications. A company that is trying to enforce FIFO (first-in, first-out) and quality hold. A company that is seeking a technology partner that specializes in helping companies in the manufacturing industry computerize and customize existing systems and processes. A company that is ready to take control!

Why ERC?

ERC user-friendly all-in-one solution, either integrated with ERP or stand-alone, eliminates the need to purchase any additional modules or systems such as warehouse management, work order production, scheduling, and quality control.

An expert project manager will drive a quick non-disruptive implementation including hardware/software installation, user training, and24/7 technical support. ERC also comes with short training videos in every module for continuous user assistance.

ERC provides smart tools and business analytics to maximize profits.

Seeing is believing, witness ERC in action by scheduling an in-person system demonstration with one of our gracious clients located in Los Angeles, California.

WAREHOUSE

- Receiving Module

- Return Module

- Cycle Count Module

- SO Staging Module

- Shipping Module

- Automated Tracking

- More…

PRODUCTION

- Work Order Module

- WO Staging Module

- Lot Cost Calculated

- Variance Reasons

- Reports And Analysis

- More…

SCHEDULING

- Electronic Scheduling

- Electronic WO’s

- Manage Direct Labor

- Real Time Production

- Reports & Analysis

- More…

QUALITY CONTROL

- Assign Hold Codes

- Disposal Approval

- Reports & Analysis

- More…

REAL-TIME ALERTS

- FIFO Violations

- Unauthorized Activities

- High Usage Variances

- Short Shipping Customer

- More…

EXECUTIVE DASHBOARD

- Margin By Lot

- Productivity Variance

- Line Utilization

- Usage Variance

- Inventory Analytics

- Shop Floor Monitor

- More…