NUMECA International

- Home

- Companies

- NUMECA International

- Software

- FINE /Turbo - Rotating and Non-Rotating ...

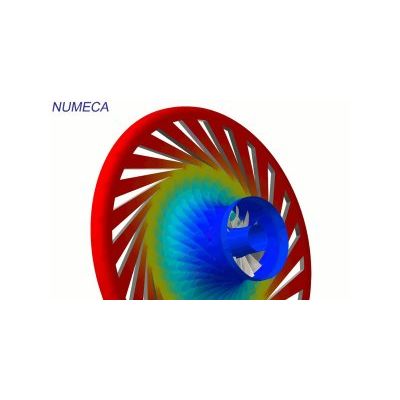

FINE /Turbo - Rotating and Non-Rotating Flow Analysis Software

Flow Integrated Environment for rotating and non-rotating flow analysis in external and internal turbomachinery applications. Recognized as the fastest and most accurate CFD suite by the worldwide turbomachinery community.

Most popular related searches

- AutoGrid5™: Automated grid generator for turbomachinery configuration, delivers the highest quality structured meshes with minimum user input. Its Wizard mode handles all types of rotating machinery configurations and complexities.

- FINE™/Turbo flow solver: 3D Navier-Stokes flow solver, recognized as the fastest and most accurate for turbomachinery configurations. Acceleration of several orders of magnitude is achieved thanks to the CPUBooster™ technique, NLH approach and HPC scalability.

- CFView™: Advanced post-processing tool, provides dedicated flow visualization and analysis outputs in an easy-to-use turbomachinery-oriented mode.

- Wizard mode: optimal mesh topology based on configuration

- Advanced geometry features: blade fillets, axisymmetric and non-axisymmetric effects

- Advanced configurations: multistage, bulb, by-pass

- Automated blocking and meshing of axisymmetric effects

- Python scripting technology

FINE™/Turbo flow solver:

- One single code for all types of fluids (incompressible, low-compressible, condensable and fully compressible) and speed (low speed to hypersonic regime)

- Acceleration with the CPUBooster module provides 3-5 times gain in convergence speed

- Non Linear Harmonic (NLH) module for full unsteady rotor-stator interactions with gains of 1 to 3 orders of magnitude in CPU time

- HPC for high performance computing on supercomputers with linear speed-up on up to 5,000 to 10,000 cores

- Embedded fluid structure interaction with the Modal and Flutter Analysis module

- Uncertainty Quantification module to study the variability of input parameters

- Automated performance curve creation

- Multigrid convergence acceleration

- Full Non-Matching Boundaries capability

- Laminar-turbulent transition

- Cavitation

- Python scripting technology

CFView™:

- Multi-projects and multi-views graphical user interface

- Specific turbomachinery visualization mode

- Python scripting technology