- Home

- Companies

- Flite Software NI Ltd

- Software

- Gas, Compressible Flow System

Gas, Compressible Flow System

Accurate for both low and high velocity gas flow systems. Solves the conservation equations and an equation of state ensuring an accurate solution. Auto-detection of choked flow conditions.

FluidFlow uses a calculation procedure that solves the conservation equations together with an equation of state for small pressure loss increments. This means FluidFlow obtains a much more rigorous and accurate solution reflective of actual plant performance. Available equations of state include: Benedict-Webb-Rubin, Peng-Robinson, Lee Kesler.

Comprehensive Fluid and Equipment Databases

Comprehensive databases of over 1200 fluids and over 800 equipment components included as standard. Databases are used extensively in FluidFlow in order to reduce the volume of data entry.

New fluids (including petroleum fractions), fluid mixtures and components can be quickly and easily added.

Databases that describe the performance and limits of fluid equipment items

Library of pipe materials, insulation materials and soil types for buried pipe calculations.

Database of manufacturers, costs, and user-defined areas of application.

Automatic Equipment Sizing Technology

Powerful Automatic Equipment Sizing technology included. FluidFlow will propose the most economical pipe size based on physical property data, capital equipment cost and energy costs.

Automatically size relief valves and bursting disks to ISO and API standards.

Pumps can be automatically sized based on either a design flow rate or design pressure rise across the system.

Automatically size pipes or ducts based on any of the following three methods; 1) Economic Velocity, 2) By Velocity and 3) By Pressure Gradient.

Heat Transfer Functionality Included

FluidFlow includes heat transfer functionality on all modules. Engineers can study heat transfer effects at heat exchangers, pipes and junctions. FluidFlow can model shell and tube exchangers, plate exchangers, coils and autoclaves.

Choose from a range of heat transfer options:

Buried pipe calculations.

Pipe heat loss/gain calculation.

Fixed heat transfer rate.

Fixed temperature change.

Ignore heat loss/gain.

Dynamic Analysis

Scripting allows the user to perform dynamic analysis on a model. These time-dependent simulations allow investigation into tank fill/drain times, system pressure as demands vary, control philosophies, and more.

Scripting can be used to perform a wide range of dynamic simulations including:

Analyse system pressure as demands vary.

Investigate system control philosophies.

Evaluate valve performance for variable speed pumps.

Flare stack depressurisation.

Optimise pump and system performance.

Analyse scale build-up in systems and study the effect on flow rate.

Design

Solve complex gas/vapor flow systems including gas mixtures.

Ensure accurate designs for both low and high velocity flow systems.

Achieve an accurate solution reflective of actual plant performance and take account of the Joule-Thomson coefficient.

Analyse

Ensure accurate gas flow system design by employing specific gas calculation procedures that solves the conservation equations together with an equation of state for small pressure loss increments.

Consider physical property changes such as pressure, temperature, density, velocity etc as gas flows throughout the piping network.

Automatically detect choked flow conditions.

Size

Model gas regulators using either the ISA (Standardized Method) or Universal (Traditional Method) Gas Sizing Equations.

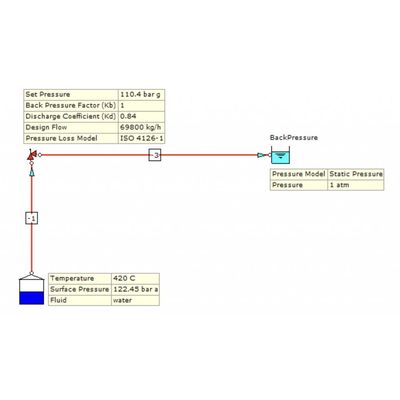

Size safety relief valves to API RP 520 Part 1 or ISO 4126-1.

Consider different pipe and duct geometry configurations including cylindrical, rectangular/square and annulus.

Communicate

Fully customisable reports allow for effective communication to colleagues, clients and peer review.

Customise flowsheet to visually communicate key results and design information.

Develop a clear and transparent design audit trail.