CFR Engines Canada ULC

IQT Research - R&D Flexibility and Customization Upgrades

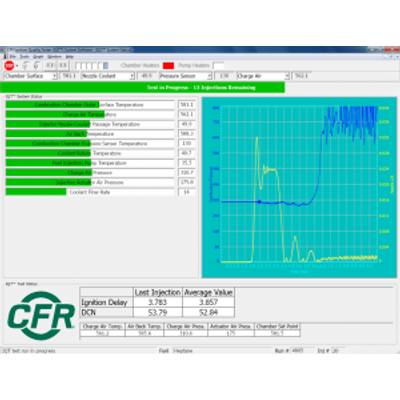

IQT Research offers essential upgrades for LM or TALM model engines, enhancing research and development capabilities through hardware and software enhancements. These upgrades are designed specifically for advanced testing environments, providing researchers with the ability to implement long ignition delays, unusual test conditions, and flexible test designs. A key feature of the upgrades is the upgraded software, which allows users to easily vary critical combustion parameters such as temperatures and pressures. These variations can be conducted with precise control, and all data from the combustion event and its trace is thoroughly captured. This level of customization and data capture makes the IQT Research upgrades a valuable tool for engineers and developers who are working on innovative combustion research and need reliable data for analysis and development.Most popular related searches

air cooling system

cooling system

injection pump

compressed air

pneumatic actuator

pressure sensor

displacement pump

liquid cooling system

conductivity controller

pneumatic nozzle

The IQT Research upgrades include hardware and software additions to LM or TALM models that allow for advanced testing customization in a research and development environment. Accommodations such as long ignition delays, unusual test conditions, and flexible test design are provided with the Research upgrades. In addition, the upgraded software allows for easy variation of key combustion parameters (temperatures and pressures), with full associated data capture of the combustion event and trace.

- A variable displacement pump (VDP): Allows for rapid, repeatable and easy adjustment of the Mass of Fuel Injected, to control the Fuel-Air Equivalence Ratio of the various test fuels

- Injection pressure sensor and high-pressure injection line, with faster A-D board: Provides the ability to capture the high pressure, injection pressure waveform as it relates to injector needle lift, and permits a more in-depth analysis of the effects of various fuel compositions on the combustion process. The benefits of being able to monitor dynamic injection pressure precisely is an important aspect of fuels, combustion initiation and combustion research.

- IQT Dimensions: 173cm (68 in) H X 106 cm (41.5 in) W X 73 cm (28.5 in) D.

- Power Requirement:

- 20A, 240VAC, 50/60 Hz

- Protected by an Uninterruptable Power Supply (UPS) and isolation transformer

- Air Supply:

- Compressed air, 20.9 % O2 ± 1.0%

- Regulated: 21.7 bar (310 psi) – Combustion process

- 12.1 bar (175 psi) – Injection process

- Nitrogen Supply:

- Compressed nitrogen, industrial grade

- Regulated: 3.5 bar (50 psi) – Fuel feed process

- Cooling System: Closed-circuit liquid to air cooling system

- Fuel Injection System (Patent Pending): Pintle-type, single hole nozzle with pneumatically actuated fuel injection pump

- Computer and Instrument Control: Rack mount computer system with automatic software backup and hot-swappable drives