TANA- North America

- Home

- Companies

- TANA- North America

- Software

- Tana ProLoc - Landfill Management ...

Tana ProLoc - Landfill Management Software

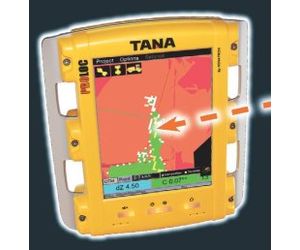

Tana`s ProLoc is available only for Tana Gx Series landfill compactors as an extra option and it is called TANA ProLoc stant. It is a real help in planning and carrying out daily operations on a landfill and an additional tool for improved work safety.

Most popular related searches

landfill compactor

landfill

level indicator

waste report

landfill operator

landfill management

landfill operation

workplace safety

color measurement

air monitoring

TANA ProLoc provides for

- optimized landfill space usage

- profitability and remarkable savings and efficient volume reduction

- effortless use

Why TANA ProLoc?

TANA ProLoc is a satellite navigation based tracking system that provides centigrade-accurate information on the landfill compactors movements.

Optimized landfill space usage and efficient volume reduction

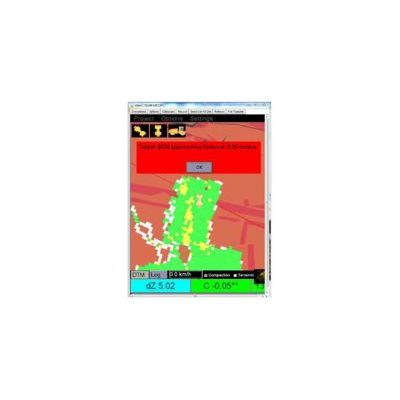

- A digitally imported filling plan gives the operator a real-time view of the work process through a colour 3D interface

- Reached compaction level is indicated by coloured squares

Profitability and remarkable savings

- No unnecessary compaction passes means up to 12 % less fuel consumed and remarkably higher compaction rate

- Machine uptime is maximized for efficient operation as idle machine time and unplanned transfers decrease

- Data is stored to a log file for progress reports and later load location information

- Provides for an even surface and uniform density on the entire landfill

Effortless use

- Clear, colour touch screen with Windows-based software

- Online downloading of work plans and software updates

- Remote connection enables trouble-shooting and problem solving

- Communication to and from cabin through interface

- Follow-up from computer display wherever internet connection is available

TANA ProLoc

- is a highly innovative system for daily landfill operations

- is available for all Tana G and Gx Series landfill compactors and may also be installed to an existing G or Gx machine prerequisite of availability of electricity, gprs connection and a digital filling plan

Volume measuring

- Filled air-space during a certain period of time

- Enables waste density measuring

Coloured chart showing the number of machine passes

- Optimises compaction work on active filling area

- History can be cleared whenever needed

- Satellite navigation based system to measuring capaction results in real-time

- More waste per yard of airspace resulting in increased profits

- Digitally imported plan gives the operator a real-time view of the work face -- 3D interface

- Desired compaction levels are indicated by colored squares

- Reduction in compaction passes results in:

- 10% or higher less fuel consumed

- 10% or higher less labor

- 10% or higher less other operating costs

- Possible to pinpoint location of specific waste

- Reports with results sent to one or more through email or text

- Windows-based software with online downloading of work plans and software updates