- Home

- Companies

- Blade Diagnostics Corporation (BDC)

- Software

- IBD HCF - Life Cycle Management ...

IBD HCF - Life Cycle Management Software

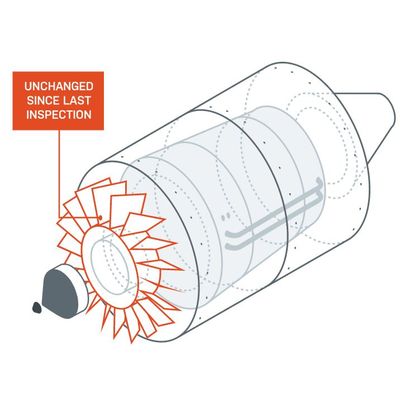

An IBD’s risk of developing High Cycle Fatigue (HCF) problems can change dramatically over its lifetime. Blade Diagnostics provides the tools to monitor HCF health over the life of the part, so you can keep your fleet operating safely.

Monitor HCF Risk

The engine environment can be hard on IBDs. Over their lifetime blades may wear, erode, or be damaged by foreign objects that are drawn through the engine. These changes can dramatically increase a part’s risk of developing HCF problems. Blade Diagnostics helps you monitor and control HCF risk over the lifetime of your parts.

Detect High Risk IBDs

EzVIBES automated evaluations allows the quick assessment of the HCF health of IBDs at scheduled maintenance intervals and after repairs. This routine monitoring detects potential HCF problems before parts fail, reduces maintenance costs, and improves fleet readiness.

Repair High Risk IBDs

Blade Diagnostics’ Life Cycle Management System extends beyond simply monitoring the fleet and flagging at-risk parts. If an IBD is found to have a high risk of developing HCF problems, Blade Diagnostics tools can guide repairs to reduce the part’s vibration levels so it can safely be returned to service.

Root Cause Analysis

If an IBD is found to have a high risk of developing HCF problems, Blade Diagnostics’ tools guide repairs to reduce the part’s vibration levels and return it safely into service.

- Reduce the risk of on-wing failures

- Minimize the cost and impact of HCF

- Repair and recover high risk parts

- Go/no-go criteria

- Data tracking for HCF fleet prognostics