- Home

- Companies

- LK Metrology Ltd.

- Software

- LK Metrology - Version CAMIO - CMM ...

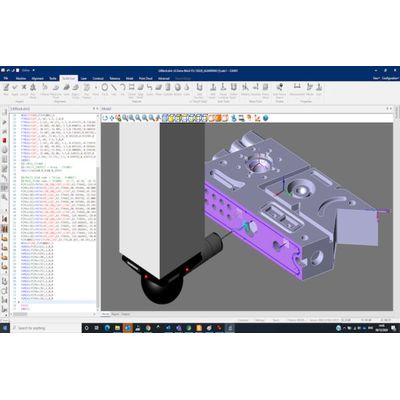

LK Metrology - Version CAMIO -CMM Multi-sensor Metrology Software

Proven in the most challenging application environments CAMIO is the CMM software of choice for many of the world’s largest manufacturers. By leveraging the productivity benefits of CAMIO, manufacturers can focus on accelerating lead times and improving product quality while reducing costs. CAMIO’s interoperability across CMM platforms, sensor technology and manufacturing sites, is a unique advantage which guarantees the sustainability of your investment in software and inspection programs.

LK Metrology is renowned for innovative CMM hardware and software solutions, and has been credited with many industry firsts, including the first bridge-style CMM, first high accuracy horizontal arm CMM and first software developed specifically for CMMs.

Our technologies underpin the process chain from design, development, production and assembly through to quality assurance in global industries such as automotive, aerospace, defence, motorsport, energy, medical and contract inspection.

This combination of technology and expertise enables us to develop solutions that provide unique and proven capabilities. CAMIO has core competencies that provide real enhancements to benefit each stage of a production process. By leveraging these benefits to improve product quality, reduce cost and accelerate lead times, manufacturers gain a real and measurable competitive advantage.

To be competitive in a global market manufacturers need to take full advantage of the most efficient, innovative and capable technologies.

Whether a small company with one CMM or large organisation with multiple installations, CAMIO provides a CMM software solution to match your business requirements and safeguard your investment.

This new version demonstrates a strong development commitment and direction for the platform, with key new functionality and significant advances particularly for automated programming.

- Major developments to support Product Manufacturing Information (PMI).

- Automated programming using PMI.

- Management and visualisation of PMI.

- New CAD importer with improved performance.

- Additional CAD file import/export capabilities.

- SLK25 VIVID CMM laser scanner support.

- Clearance planes for probe safety moves.

- Linear and radial slices for touch points and scan paths

- Datum modifiers for profile and position tolerances.

- Automated tolerance algorithms based on GD&T.

- Slot position, width and length tolerance methods.

- Standard deviation elimination filters for surfaces.

- Additional user-defined custom XML output.

- Commands for save and recall of program settings

- Microsoft Windows 11 support.