Mar-Kov Computer Systems Inc.

- Home

- Companies

- Mar-Kov Computer Systems Inc.

- Software

- Mar-Kov - Manufacturing Execution ...

Mar-Kov - Manufacturing Execution Software

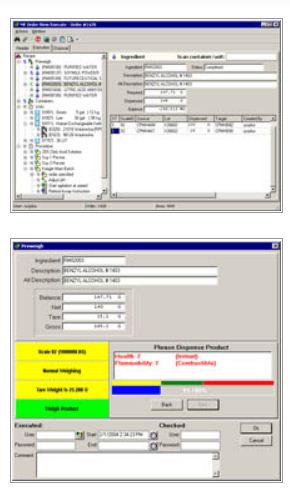

Prompts and Polices the pre-weigh, comingle, and batching operation. May be integrated with your existing ERP system so that consumption information is relayed within seconds to the host system.

Most popular related searches

- Real time consumption and creation of inventory.

- Computer assisted weighing, blending, and packing out of manufacturing orders.

- Provides accurate real time inventory visibility and quality control status to operators.

- Pre-weigh and co-mingle operations are performed using scales that are directly accessible to the software, enhancing speed and reliability.

- Each step of the batching operation is policed by the software in order to ensure that all steps are performed as defined in the process specification.

- MSDS and HMIS information is displayed as required throughout.

- The software ensures that all equipment has been cleaned and sanitized before allowing it to be used.

- Provides an electronic batch sheet that may be customized by the user.

- Paperless system with data collected at the source eliminates time and errors associated with manual data recording and entry

- Increase manufacturing efficiencies by 10%-30%

- Complete lot traceability with container level tracking of source materials.

- Material consumption information is sent back to the host ERP in seconds.

- Ability to interface to ANY host system: Oracle, SAP, Batchmaster, MFG/PRO Data3, etc.

- Designed to meet the stringent requirements of the FDA with 21 CFR Part 11 Compliance

- Designed to work in a thin client environment, which lets the application run on portable Pocket PCs or Pen tablets

- Barcoding is used throughout to ensure accuracy

- Maintains an inventory of misblends and automatically recommends their use when possible.

- Integrated in process testing ensures that adjustments are correctly completed, and retains details for review and analysis

- Automatically corrects quantities required based on the purity as required, and determines the amount of filler required.

- Weight tolerances can be set at the ingredient level.

- Gang weighing is supported for increased efficiency.

- Filters ingredients by workstation based on security, size of pour, and other criteria.

- Signatures for operator and checker can be individually configured for each operation.