- Home

- Companies

- Third Dimension Software Ltd

- Software

- Third Dimension - Version SPC3d - ...

Third Dimension - Version SPC3d -Measurement Software

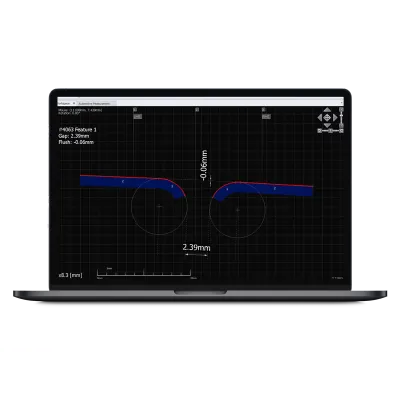

SPC3d is a robust measurement software designed to facilitate the creation of check plans that guide operators on precise measurement locations. It seamlessly integrates with Third Dimension's GapGun® and Vectro®2 precision measurement tools, allowing users to inspect parts either inline or offline efficiently. The software supports high-performance processing through multi-core technology, enabling rapid and simultaneous measurement of up to ten dimensions. With its advanced algorithm, SPC3d can manage non-standard shapes and analyze diverse surface finishes. It offers flexible data logging and is compatible with various formats like DMIS, QDAS, and CSV, ensuring smooth integration with other systems. Live measurement mode provides real-time data comparison against tolerance bands, with automatic alerts for measurement anomalies. Its virtual toolkit and customizable libraries enhance versatility, while the simple user interface ensures ease of navigation and minimal training. This software is aimed at industries requiring precise, reliable quality assessments.

High performance processing:

Multi core processing enables super-fast measurements and analysis.

Advanced measurement capability:

Cutting edge algorithm technology means SPC3d can measure up to 10 different dimensions simultaneously with scope to customise measurements on non-standard shapes. It also has the ability to analyse almost unlimited surfaces finishes.

Flexible data logging and integration:

Access data quickly and easily in a huge variety of industry standard formats, including DMIS, QDAS, MS Excel, plain text, CSV, and point cloud to enable flexible integration with other systems and corporate networks.

Live measurement mode:

Measurements are viewed onscreen in real time as data is collected and can be compared against tolerance bands.

Measurement condition alerts:

Automatic variation thresholds define good measurements and automatically report poor measurement conditions so that you can always have confidence in your results.

Flexible network connection:

Seamlessly roam or conveniently connect to any PC on a network to automatically download results.

Seamless data annotation:

Label results coherently with an option to select a ‘not-measured’ code during a check plan sequence when a measurement point is unavailable or inaccessible.

Virtual Toolkit™:

SPC3d’s extensive toolkit allows measurement of virtually any gap, flush, radius, scratch, chamfer, fastener, seal or profile. Uniquely, it also allows administrators to build customised libraries of tools.

Optimised user interface

Simply and ergonomically designed interface and menu system for ease of use, navigation and minimal training.