Tridiagonal Solutions Inc

- Home

- Companies

- Tridiagonal Solutions Inc

- Software

- MixIT - Stirred Tank Mixing Analysis ...

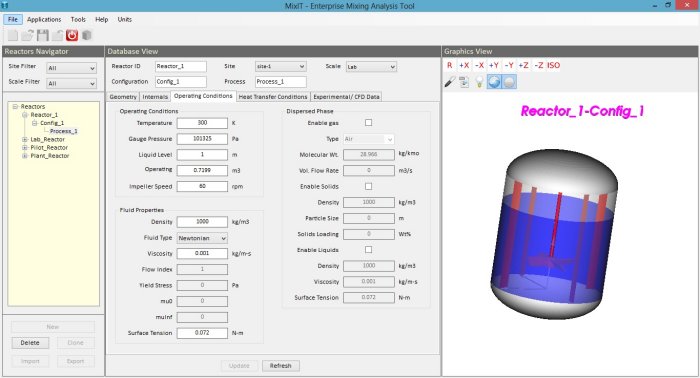

MixIT - Stirred Tank Mixing Analysis Software

MixIT is an enterprise wide deployable mixing analysis tool designed to facilitate comprehensive analysis of stirred reactor performance using lab & plant data, empirical correlations and advanced CFD models. It has an easy-to-user interface that allows quick data input with dynamic graphical feedback. Using MixIT users can create a database of their reactors across scales (lab/pilot/plant) and geographical locations and quickly understand performance of a reactor or compare performance of multiple reactors.

Most popular related searches

computational fluid dynamics

MRF process

MRF processing

velocity profiler

pharmaceutical water

velocity profile

velocity profiling

fluid dynamics

water treatment

petrochemical water

- Design stirred tanks

- Identify optimal operating conditions

- Scale processes from lab to plant

- Transfer technology across plants

- Optimize recipes and processes

- Debug mixing problems during scale up or plant operation

- Predict mixing profiles in stirred tanks using CFD analysis

- Increase in overall mixing efficiency

Chemists and Chemical Engineers involved in R&D, Process Development, Technology Transfer and Manufacturing in the following industries:

- Chemicals & Petrochemicals,

- Pharmaceuticals,

- Water Treatment,

- Biotechnology,

- Oil and Gas and agitators OEMs

- Intuitive GUI

- Extensive Impeller Library

- Select or change the number, location & dimensions of the baffles

- Industry standard bottom Shapes

- Correlation based Analysis & Performance comparison

- Flexibility of Unit system

- Fully automated CFD analysis

- Powerful Reports and Visualization tool

Database

- Quickly create a database of various reactors available in the organization.

- Database can be used to store geometry details, operating conditions, plant measurements, experimental & CFD data.

- Database can be sorted according to location of the reactor and scale.

- Add, delete, import, export single or multiple reactors from the database.

- Database can be shared across users.

Reactor Analysis

- Design a reactor to achieve a desired mixing performance.

- Quickly select multiple reactors from database & compare their performance.

- Calculate mixing parameters such power, blend time, mass & heat transfer characteristics, gas hold-up etc.

- Compare the performance of multiple reactors across scales & arrive at operating conditions that meet scale up criteria

- Optimize reactor design & operating conditions to increase the process performance.

Computational fluid Dynamics

- Perform steady state single phase CFD simulation to understand the flow pattern, velocity profile etc.

- Geometry creation & meshing, iterative simulation, post processing are fully automated.

- Perform rigorous CFD simulation using one of three impeller models: 2D fixed velocity data, 3D fixed velocity data & MRF.

- Process can be further extended to perform heat transfer analysis.