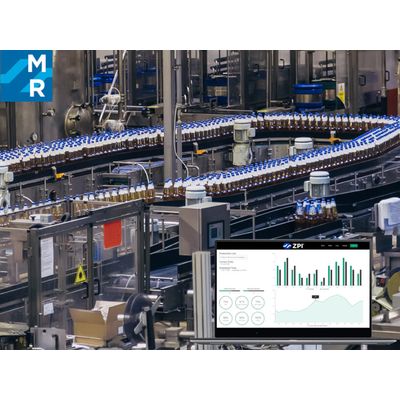

ZPI - Monitor & Report Automatic Production Line Data Collection & Reporting

Packaged goods manufacturers have taught us three very important things: Nothing is more expensive than downtime. Nothing is more valuable than reducing it. Opinions, conventional wisdom and never-ending debates about what is really causing downtime rarely lead to eliminating it.

What does help eliminate downtime are facts, data, and objective determinations of what is going on with a production line.

ZPI Monitor & Report provides real-time 24/7/365 visibility into the performance of every machine in a production line.

It does this by capturing, aggregating and storing every signal from every piece of equipment in a production line, from inbound raw material handling to palletized finished product. If something happens on a machine anywhere in a production line, Monitor & Report captures it and customers can analyze it.

Monitor & Report provides real-time, fact-based alerts and insights into critical production line questions:

- What happened?

- Where in the line did it happen?

- When did it happen?

- How long was the machine or line down?

- Why was the machine or line down?

Monitor & Report empowers manufacturers to quickly identify and troubleshoot production problems and it provides fact-based analytic support for a wide range of continuous improvement initiatives including Overall Equipment Effectiveness (OEE).

It is used around the world by customers of all sizes from a wide range of industries including ready-to-drink beverages, beer, distilled spirits, baked snacks, frozen pizza, candy, ground coffee, canned meats, nutritional products, yogurt, automotive lubricants, automotive fluids, paint and pharmaceutical products.

- Return On Investment (ROI) Measured In Weeks Or Even DaysLost productivity is so costly that even eliminating a few hours of downtime a week can pay for a Monitor & Report installation

- 100% Turnkey Installations & Implementations By ZPI PersonnelEntire installation and start-up process 100% completed by ZPI personnel which means no distractions for customer personnel

- Zero Downtime InstallationNormal production schedules are maintained; eliminates need to schedule downtime for system installation

- 100% Software Solution: No proprietary Hardware And No Machine PLC Programming Changes RequiredNo new or specialized equipment required and no machine programming changes reduce implementation expense and headaches

- Unlimited System Users, Unlimited System Access, Unlimited Reporting and Unlimited Report FormatsProvides cost effective system access with no upcharges for additional users, additional capabilities, or remote users

- Supports A Variety Of Continuous Improvement InitiativesKey Performance Indicators (KPI), Overall Equipment Effectiveness (OEE), Total Productive Maintenance (TPM), Six Sigma

- Real-time “Machine-down” or "Line-down” AlertsHelps accelerate troubleshooting and implementation of corrective actions

- Real-time “Plan Versus Actual" Progress ReportingHelps shift managers or line leads stay on-top of achieving daily production targets

- Comprehensive, Real Time Line Monitoring & Data CaptureEvery signal from every piece of equipment in a production line is captured during line operation

- Intuitive User InterfaceSupports access and use by every functional area in the business including operations, maintenance, production planning, finance and HR

- Instant Access To Both Real Time & Historical Production Line Performance DataSupports trend analyses, year over year, shift vs shift, month vs month comparisons, or quick summaries of what happened in the last hour. With a comprehensive historical database updated in real time, the system enables every type of analysis imaginable

- Unlimited Analytic Reporting Tools With Both Standard & Custom Report FormatsFlexible reporting options assures every user can have reports containing exactly the information they need in exactly the format they want

- Monitor & Report software lives on a customer`s local area network.Eliminates IT security concerns with remotely hosted software.