- Home

- Companies

- Arizona Optical Metrology

- Software

- Morpheus - Data Reduction Software

Morpheus - Data Reduction Software

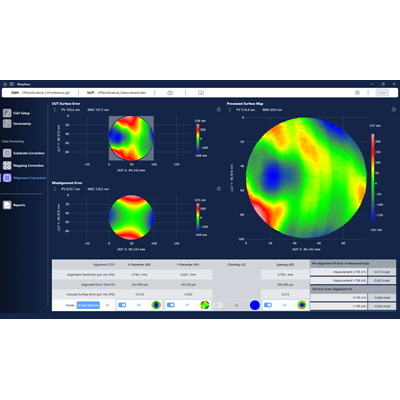

Morpheus is a specialized software designed for computational tasks related to CGH data reduction, transforming raw measurement data into accurate results efficiently. The software features an intuitive user interface, real-time visual feedback, and tools tailored for complex optical metrology. Morpheus enhances workflows in the analysis of intricate optics by performing misalignment correction, mapping correction, and substrate correction. This ensures precise convergence on optical surfaces during polishing processes. It offers a comprehensive system for conducting uncertainty analysis, covering CGH parameters, design residuals, and test geometries. Additionally, Morpheus enables clear documentation by generating reports of the test results essential for production traceability. The software supports custom surface tests that integrate a digital twin CGH file, facilitating the processing of measurement data, improving confidence in outcomes, and optimizing metrology operations.

Morpheus™ is a powerful CGH data reduction software that transforms raw measurement data into accurate, refined results in just a few clicks. With an intuitive UI, real-time visual feedback, and purpose-built analysis tools, Morpheus streamlines metrology workflows for complex optics—ensuring confidence in every measurement.

Misalignment Correction

Automatically fit and remove error contributions from misalignment in CGH tests, enabling fast convergence on surface figure for optical surface generation. Benefits include:

- Removing the exact misalignment modes from data – no more guessing at Zernike approximations or living with error due to misalignment

- Production time savings – obtain “good enough” alignment of the test setup and remove residual alignment errors in software with proven consistent results

- When used in conjunction with AOM auxiliary alignment patterns, misalignment modes indicate optical surface alignment to mechanical datum features

Mapping Correction

Convert and scale CGH measurement data to the coordinate frame of the test optic, a critically important step for convergence in deterministic polishing and finishing processes.

Substrate Correction

Remove the transmitted wavefront error contribution of the CGH substrate from your measurement, reducing measurement uncertainty.

Factory-calibrated substrate error is automatically registered to measurement data and subtracted, ensuring precise and reliable measurement data.

Uncertainty Analysis

Analyze the total uncertainty stack up of as-built CGH parameters, design residuals, and test geometry uncertainty.

Provides test uncertainty analysis for key aspects of the test – alignment, measurement, and CGH contributions. Benefits of this feature include:

- Understanding test uncertainty including the as-built CGH parameters before even making a measurement!

- Estimating uncertainty due to misalignment to enable understanding of setup requirements.

Report Generation

Quickly output relevant test results and processing steps in a clean report format for production traceability requirements.

- Each custom surface test CGH can include a “digital twin” CGH file (.cgh) which contains all of the data required to process measurement data Morpheus.

- The Morpheus software application is included with the purchase of a .cgh file, no separate licensing fee or other restrictions exist.

- Ask your AOM representative to include the optional .cgh file with your next CGH procurement to start using Morpheus in your lab!