- Home

- Companies

- New River Kinematics (NRK), Inc

- Software

- NRK SpatialAnalyzer - Version SA - ...

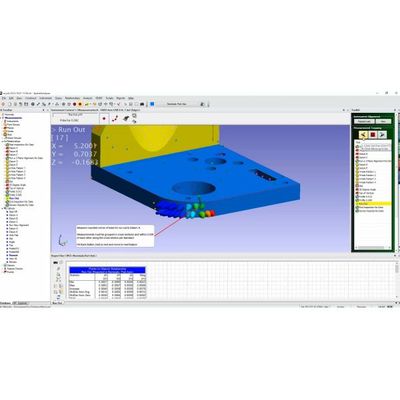

NRK SpatialAnalyzer - Version SA -Portable Metrology Software Solution for Large-scale Applications

SpatialAnalyzer is the premier portable metrology software solution for large-scale applications. SA is an instrument-independent, traceable 3D graphical software platform that makes it easy for users to integrate data from multiple instruments and perform complex tasks simply, ultimately improving productivity. Click below for watch a video that will introduce you to the power of SA.

SA is a highly flexible, instrument-independent, traceable 3D graphical software platform that makes it easy for users to:

- Inspect parts

- Build

- Analyze data

- Report

- Reverse design

- Interface with virtually any type of portable metrology instrument

- Automate complex operations to improve measurement and inspection efficiencies.

SA helps customers achieve the following:

- Address a broad spectrum of problems ranging from simple to complex

- Save time, money, effort, and ultimately improve productivity

- Establish ROI and accomplish goals that were previously impossible.

Instrument-independent, SA can simultaneously communicate with virtually any number and type of portable metrology instruments while performing complex tasks simply. SA can also integrate data from multiple instruments and help users find the best optimization to improve accuracy, save time, and reduce scrap. Interfacing with 120+ instruments (Laser Trackers, Local GPS, Portable CMM`s, Theodolites, Total Stations, Laser Scanners, etc), SA provides simple, common interfaces for each instrument class.

Since its inception, SA has been involved in innovative, cutting-edge applications in almost every industry involving large-scale manufacturing. SA adopters include leading manufacturers around the globe in the aerospace, shipbuilding, energy, satellite, and automotive industries.

SpatialAnalyzer® (SA) is the premier portable metrology software solution for large-scale applications. Put simply, SA helps users save time, money, and resources. Click here to access the SA fact sheets and for a detailed features matrix.

Full Support for Multiple Portable Metrology Instruments

Powerful, versatile, and user-friendly, SA can simultaneously communicate with virtually any number and type of portable metrology instruments. This includes laser trackers, arms, laser radars, scanners, projectors, theodolites, total stations, and photogrammetric devices–all featuring a common interface for each instrument class.

Alignment

Align to a known coordinate system using a variety of techniques, from 3-2-1 and best fits to interactive fitting such as Quick-Align and classic surface fits. Relationship Fitting allows for simultaneous feature-based fitting to organic surfaces in addition to traditional iterative fitting.

Real-Time Build & Virtual Assembly

Digitally assemble components with relationships and constraints to see how parts will fit in final assembly. An entire suite of tools are available for real-time building.

Traceability

Maintain a clear history of all data from start to finish with 100% traceability from measurement to reporting.

GD&T Inspection

Address ASME standard GD&T requirements with support for native CAD annotations.

Reporting Tools

Quickly and easily generate custom reports with output to a wide variety of formats.

Point Clouds

Combine laser scanner interfaces with advanced tools for feature fitting and automatic sphere extraction. Automatically extract features from scan data for easy comparison to CAD or analysis with GD&T.

Uncertainty Calculation & USMN

Calculate measurement uncertainty and use USMN to achieve the ideal instrument network.

Geometry Inspection

Define design-based inspection routines from a CAD model or primitive geometry.

Model-based Definition

Take advantage of CAD models to capture deviations over time or watch them in real-time.

Automation

Use Measurement Plans and an SDK to enable powerful scripting and automation capabilities.

SpatialAnalyzer® (SA) is the essential measurement, alignment, and reporting software for all portable metrology instruments in large-scale manufacturing settings. There are two main SA software packages that address different precision measurement needs and goals. Both SA packages can simulateously communicate with virtually any number and type of portable metrology instruments. Custom software solutions are also available for customers with unique metrology challenges.

SA Professional

SA Professional with Native CAD is the professional measurement, alignment, inspection, analysis, and reporting software for all portable metrology instruments. In addition to all essential measurement needs, it includes several key inspection features, geometry inspection, and measurement automation.

Full Support for Multiple Portable Metrology Instruments

SA can simultaneously communicate with virtually any number and type of portable metrology instruments. This includes laser trackers, arms, laser radars, scanners, projectors, theodolites, total stations, and photogrammetric devices–all featuring a common interface for each instrument class.

Measurement

100% traceability from measurement to reporting.

Alignment

A variety of alignment methods ranging from traditional 3-2-1 alignments to more advanced surface fits.

Build

Relationships are dynamic in nature and update automatically if part alignment or data changes.

Evaluation & Analysis

Permits both graphical and numerical depiction of measurement uncertainty.

Reporting

Quick, user-friendly reproting functionalities.

GD&T Inspection

Import CAD with GD&T annotations, create annotations manually, and inspect to GD&T standards with real-time reporting.

Geometry Inspection

Define design-based inspection routines from a CAD model or primitive geometry.

Native CAD

Import support for such major applications as CATIA V4, V5, Pro/Engineer, SolidWorks, Unigraphics, and other CAD formats.

SA Ultimate

SA Ultimate plus Native CAD is the premier measurement, optimization, analysis, reporting, and automation software suite for all portable instruments. SA Ultimate is inclusive of everything contained in SA Professional, plus the features below.

Real-Time Alignment

Track moving parts in real-time so that you can monitor a part’s position as it is guided into place.

Advanced Fit Optimization

Provides the power necessary for advanced alignments and can help bring an out-of-tolerance part back within tolerance. You can also define fit envelopes to satisfy multiple constraints/ requirements.

Complex Instrument Networks (USMN)

A powerful feature that leverages the uncertainty characteristics of different instruments to provide a much more accurate instrument network than that of traditional alignment methods.

Automation

Generate simple to complex scripts that will greatly improve workflow and productivity, eliminate errors and save significant resources.

Pipe Fitting

Used in large piping applications when precision measurements and optimization are required.

Database Output

An additional reporting feature that allows you to transfer SA data to databases and track projects/data long-term.

SA Analysis

SA Analysis includes all functionality of SA Ultimate without the ability to connect to a device.

SA Robot Calibration Appliance

The SA Robot Calibration Appliance gives you the ability to implement a calibrated kinematic model of the robot within your native robot language programs. So, from the robot language, you can trigger metrology measurements at various robot poses, run a calibration on that data, and then use the calibrated model as you continue your program, moving the robot as you normally would.

This is accomplished through a small, stand-alone, computer that the robot controller can communicate with in order to access the calibrated kinematics. This means that you never have to modify the kinematic model that is internal to the robot. Instead, the calibration appliance allows you to work around it and use an external, calibrated, kinematic model. An added feature is that you can easily switch between multiple kinematic models for different areas of focus. This allows you to locally calibrate the robot for a task and gain even higher accuracy.

The metrology measurements used in the calibration process are taken using the SpatialAnalyzer (SA) measurement platform. You simply connect SA to the calibration appliance over the network, and then the appliance will trigger measurements as required by your robot program. Once the calibration is complete, SpatialAnalyzer is no longer required and the SA Robot Calibration Appliance can serve up calibrated kinematics to the robot as a stand-alone device.