- Home

- Companies

- Virtuosity, A Bentley Company

- Software

- AutoPIPE - Pipe Stress Analysis and ...

AutoPIPE - Pipe Stress Analysis and Design Software

With extensive interoperability across other industry applications as well as time-saving features like the new support optimizer, AutoPIPE helps ensure quality, cost-effective designs, and a smooth workflow for the engineers who use it for pipe stress and analysis.

- Save time with an easy-to-use application

- Perform advanced analysis and design

- Create graphical results and reports

- Streamline multi-discipline workflows

- Optimize pipe supports

- Quality assurance

What is AutoPIPE? What is AutoPIPE used for?

When the deliverable is reliable pipe and vessel designs, there is no need to spend time doing something your software can do for you. AutoPIPE is an analysis and design application used to calculate piping stresses, loads, and deflections under static and dynamic load conditions. With extensive interoperability across other industry applications as well as time-saving features like the new support optimizer, AutoPIPE helps ensure quality, cost-effective designs, and a smooth workflow for engineers who use it.

AutoPIPE is available in various versions. Find out which version is right for you.

- AutoPIPE

- AutoPIPE Advanced

- AutoPIPE Nuclear (Sold directly by Bentley)

How does AutoPIPE help with pipe stress analysis?

With AutoPIPE, you can:

- Save time with an easy-to-use application

Easily create and modify pipe stress models by using the object-based OpenGL graphical user interface. You can simply point and click to insert, modify, or delete components for instant visual updates and modify parameters across a range of points with just one command. Tracking changes or making modifications can be done in a snap to help save time and eliminate otherwise cumbersome tasks.

- Perform advanced analysis and design

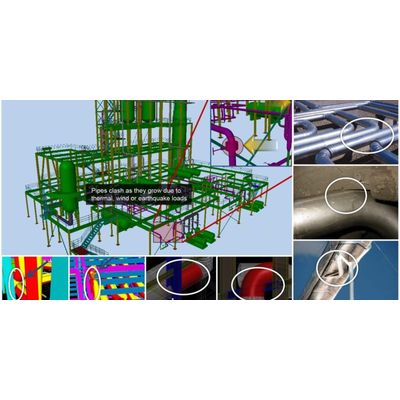

Perform design and analysis for buried pipelines, fluid transients, wave loading, and FRP/GRP or plastic pipe and avoid piping failures and costly shutdowns by evaluating your design under extreme loading conditions like earthquakes. With AutoPIPE’s 3D hot clash detection you can eliminate errors up-front and perform ‘what-if’ analysis to quickly evaluate various design scenarios.

- Streamline multi-discipline workflows

Integrate piping and structural analysis and design with the ability to transfer pipe support loads and import complete structures to and from other applications. AutoPIPE interoperates with applications like STAAD.Pro, SACS, OpenPlant, and CAESAR, so you can save design time and streamline the workflow when working across various teams.

- Optimize pipe supports

Provide the most optimized pipe support design quickly using the latest AI machine learning technology. When a piping system must be designed to withstand various stresses, it`s critical to assess loading points and support them adequately, yet keep costs to a minimum. The new support optimizer feature allows you to create thousands of design alternatives and compare them as they become available. Then make iterations until the best outcome is achieved.

- Create graphical results and reports

Produce customized reports in various formats from an open-sourced, optimized SQLite database and eliminate tedious reviews with color-coded results and pop-up windows that help identify and investigate critical issues.