HammerTech

- Home

- Companies

- HammerTech

- Software

- HammerTech - Plant and Equipment ...

HammerTech - Plant and Equipment Management Software

FromHammerTech

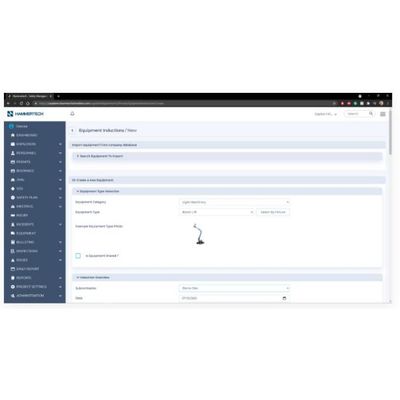

Ensuring plant and equipment has been maintained and is fit for use is essential for the safety of operators and neighbouring workers. Keeping track of every piece of plant on a large site can be complicated. The Plant and Equipment module takes control of this process, making it simpler to monitor all plant and equipment on-site.

Most popular related searches

- Plant and equipment register that automatically updates as equipment comes to site.

- Automatic notifications sent to management, site teams and subcontractors when plant & equipment require servicing.

- Link equipment to relevant JHAs and authorised operators. HammerTech automatically verifies whether operators are appropriately licensed to operate equipment on site.

- HammerTech generates QR codes for equipment which operators can scan to conduct pre-start or servicing checks.

- Customize plant checklists / documentation requirements / photos of plant to ensure all required information is captured at orientation.

- No manual work required to update plant registers.

- Better management of plant servicing, reducing the risk that plant is being operated outside of servicing dates.

- Additional checks in addition to a plant inspection to ensure safe procedures are in place for use of the plant.

- Records can be easily accessed on site. Searching for the plant sticker number results with the records of that piece of plant including relevant documentation, authorized operators, servicing and pre-start history.

- Plant checklist forms can be customized to meet your specific requirements.

- Automatic notifications when servicing is required or operator licenses are due to expire.

- Centralized plant orientations - once equipment is orientated onto one site it can be transferred and tracked between all sites.