- Home

- Companies

- HGG Profiling Equipment

- Software

- HGG ProCAM - Proprietary Software for ...

HGG ProCAM - Proprietary Software for CAD to CNC Transformation

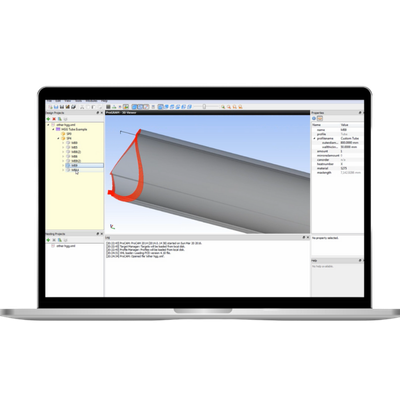

ProCAM is a proprietary software developed by HGG specifically for 3D profiling applications, translating CAD designs into executable cutting files efficiently. It supports precise cutting from CAD models, offering features like a 3D viewer for component examination, advanced nesting algorithms to optimize material usage, and real-time performance tracking with ProMIS. This software suite ensures seamless CAD model integration with top industry CAD/CAM applications such as TEKLA and SDS2, allowing for smooth data transfer and ensuring compatibility with HGG's cutting machines. The ProCAM suite also includes predefined macros to simplify the design process, advanced algorithms to minimize waste, and capabilities for generating various reports essential for productivity management. Furthermore, ProCAM Lite, a free component of the suite, allows detailed design review without cutting hardware. The suite's structure and features simplify transition from design to finished parts with optimized handling of materials and clear marking, enhancing the accuracy and ease of assembly.

HGG’s inhouse developed ProCAM software allows you to easily turn your CAD-designs into cutting files. From single parts to complete assemblies. It allows you to check the parts in the 3D viewer, nest the parts with HGG’s powerful nesting module, and adjust them before generating the cutting files.