- Home

- Companies

- Flite Software NI Ltd

- Software

- Slurry & non- Newtonian Flow System

Slurry & non- Newtonian Flow System

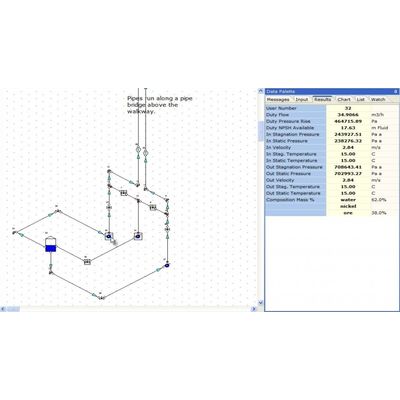

Accurately model any slurry or non-Newtonian fluid system. Design concentrate pipelines, tailings, paste backfill systems, and more. The industry choice for the design and modeling of efficient & reliable slurry flow systems.

The Slurry Module can be used to model settling or non-settling non-Newtonian fluids as well as Pulp & Paper Stock Flow Systems.

Comprehensive Fluid And Equipment Databases

Comprehensive databases of over 1200 fluids and over 800 equipment components included as standard. Databases are used extensively in FluidFlow in order to reduce the volume of data entry.

New fluids (including petroleum fractions), fluid mixtures and components can be quickly and easily added.

Databases that describe the performance and limits of fluid equipment items

Library of pipe materials, insulation materials and soil types for buried pipe calculations.

Database of manufacturers, costs, and user-defined areas of application.

Slurry Methods

Settling slurry calculation methods available include Durand, Wilson-Addie-Sellgren-Clift (WASC), WASP, Liu Dezhong and the Four Component Model. Non-settling slurry calculations methods depend on rheology data. These can be described as Power Law, Bingham Plastic, Hershel Buckley or Casson. Pulp & Paper Stock loss correlations include TAPPI & Moller K.

Simulating the performance of settling slurries is dependent on the solid density, concentration, particle shape and size distribution, as well as the properties of the carrier fluid. Selecting the optimum pipeline velocity is usually the most important factor in the design and operation of slurry systems. Fluids can be mixed on the flowsheet. This allows for dilution effects in slurries to be considered.

Automatic Equipment Sizing

Powerful Automatic Equipment Sizing technology included. FluidFlow will propose the most economical pipe size based on physical property data, capital equipment cost and energy costs.

Automatically size relief valves and bursting disks to ISO and API standards.

Pumps can be automatically sized based on either a design flow rate or design pressure rise across the system.

Automatically size pipes or ducts based on any of the following three methods; 1) Economic Velocity, 2) By Velocity and 3) By Pressure Gradient.

Dynamic Analysis

Scripting allows the user to perform dynamic analysis on a model. These time-dependent simulations allow investigation into tank fill/drain times, system pressure as demands vary, control philosophies, and more.

Scripting can be used to perform a wide range of dynamic simulations including:

Analyse system pressure as demands vary.

Investigate system control philosophies.

Evaluate valve performance for variable speed pumps.

Flare stack depressurisation.

Optimise pump and system performance.

Analyse scale build-up in systems and study the effect on flow rate.

Design

- Robust slurry pipelines by modeling heterogeneous settling slurries, non-Newtonian slurries, and complex slurry flows for broad particle size distributions that display both settling and non-settling characteristics. Pulp & Paper systems are also solved using the Slurry & non-Newtonian Module.

- Calculate system pressure losses using any of five available methods and consider solids derating (three available methods) of end suction centrifugal pumps.

- Characterise non-Newtonian non-settling slurries by defining fluid constants or a series of data-points for Shear Rate vs Shear Stress and switch between the four available rheology relationships (Herschel-Bulkley, Power Law, Casson and Bingham Plastic) and choose the relationship/curve-fit which best represents your defined data-points.

Analyse

- Pipeline velocities relative to calculated deposition velocity to ensure you avoid particle settling/pipe blockage.

- Study plant performance and determine slurry physical properties throughout the entire system, including solids delivered.

- Identify the cause of operational issues with new or existing plant and evaluate solutions. FluidFlow highlights potential problem areas including the risk of saltation/pipe blockage.

Size

- Rapid pump sizing function enabling efficient pump selection. This helps ensure your selected pumps are operating at an efficient and reliable duty-point.

- Determine pipe sizes using any of the four available correlations.

- Develop Hydraulic & Energy Grade Line (EGL/HGL) graph plots to help evaluate performance of pumps installed in series in long distance distribution lines.

Communicate

- Fully customisable reports allow for effective communication to colleagues, clients and peer review.

- Customise flowsheet to visually communicate key results and design information.

- Develop a clear and transparent design audit trail.