- Home

- Companies

- Sphera Solutions, Inc.

- Software

- Sphera - Quality Risk Management ...

Sphera - Quality Risk Management Software

You take pride in quality. Lock in a consistent approach to products and processes with our software for quality risk management. Prevent Costly Rework, Scrap, Failures and Recalls. Risk-based decision-making has become a cornerstone in many industries – especially those as critical as manufacturing medical devices, life sciences, automotive, and semiconductors. There’s risk running straight through these industries due to intellectual property, trade secrets, and the need to deliver quality products to customers.

What’s more, monitoring quality risk is difficult. And while compliance with quality regulations, standards, and customer mandates is a requirement, it’s not enough.

Did you know,

- 80% of all quality issues are repeated events

- 42% of knowledge workers’ time is spent seeking, processing and sharing information

- 30% of total R&D spend is wasted, duplicating research and work done previously*

To remain competitive, manufacturing organizations must transform and improve the efficiency of their quality management processes. They need to reduce time looking for and accessing risk assessment data. They need to consistently conduct risk assessments, access lessons learned and recommendations and improve traceability.

Companies need a standardized process and formal knowledge management systems and processes to identify, capture, manage and share critical documents and information. This is critical for managing inherent quality risks, preventing costly failures and recalls, and ensuring product quality demanded by customers.

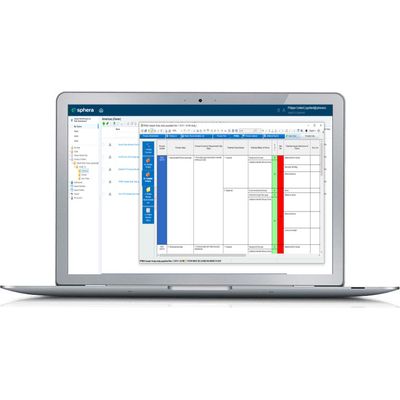

Sphera’s robust, centralized Quality Risk Management software, configurable methodologies, and risk assessment workflows will help your organization standardize and record risk assessment data and ensure proper controls are in place.

Our libraries and templates promote standardization in a common language while providing the flexibility to link information together – for example, dFMEA and pFMEA, Process Flow Diagram/Chart, and Control Plan.

This allows companies to perform quality risk assessment activities more efficiently and effectively, accelerating productivity and ensuring data integrity.

- Eliminate complex and dispersed risk documents and spreadsheets

- Create a central knowledge base to retain critical expert data

- Reduce engineering time to perform FMEAs and accelerate time to market for new product introductions

- Seamlessly link FMEA information across the design and process stages to reduce siloed risk assessments and increase productivity

- Maintain consistent and systematic measurement of all product quality risks

- Improve efficiency and reduce product quality risk by cascading changes through the APQP process