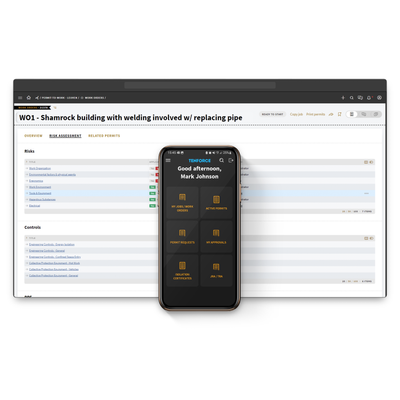

TenForce - Digital Permit-to-Work System for Safe and Efficient Workflow

TenForce offers a Digital Permit-to-Work (PTW) System designed to enhance both safety and efficiency in high-risk work environments. By transitioning from traditional paper-based methods to digital workflows, this system streamlines the entire permit-to-work process. Key features include real-time data access and instant notifications for permit expirations, ensuring operations are conducted under valid permits. Its configurable forms, based on industry best practices, support quick and accurate data entry. The system's integration with risk assessments such as JSA, TRA, and ORM, alongside real-time data from various operational aspects, enables proactive risk management. With centralization of permit storage and compliance with regulatory standards, management can maintain 100% audit readiness. Additionally, it increases efficiency by reducing time spent on administrative tasks by 75% and accelerating permit generation fourfold. With seamless integration with Lock Out Tag Out modules, TenForce’s solution transforms EHSQ processes to foster a proactive safety culture.

Request and Create Permits

- Request a PtW for a specific task, equipment and location using configurable and reusable electronic forms

- Conduct integrated safety assessments (TRA, JSA, ORM)

- Link the PtW to relevant isolations, LoTos, and SIMOPs

- Approve or reject the PtW based on the safety assessments

Integrate with Isolation Planning, Lockout/Tagout and SIMOPs

- Identify any equipment or systems that need isolation

- Follow LOTO processes and verify that the equipment is safely secured

- Identify and implement safety measures to manage simultaneous operations

Issue the Permit

- Issue the PtW once isolations, LoTo, and SIMOPs are in place

- Include details such as work duration, personnel involved, and safety precautions

- Notify stakeholders with rule-based emails and alerts

Complete the Task

- Follow the approved PtW and associated safety measures

- Monitor the status of each task, issuing automated alerts for overdue tasks

- Continuously monitor isolations, LoTo, and SIMOPs to prevent incidents

- Report any deviations, investigate and take corrective actions promptly

Close the Loop

- After completing the work, close the PtW

- Verify that all equipment is restored, LoTo is removed, and SIMOPs are ended safely

- Conduct post-job safety assessments

- Monitor active permits, inactive permits and preventive actions from a central overview

Work Smarter, Work Safer

Minimize the Risk of Human Errors

TenForce automates workflows, providing instant alerts and notifications to help you stay on top of critical tasks. Plus, timely alerts for permit expiry guarantee that work always happens under valid permits. Our electronic, configurable, and reusable forms are built on best practices and encourage quick, accurate and standardized data entry.

Save Time on Administrative Tasks

Leave behind time-consuming paper-based systems as TenForce digitizes every aspect, from creation to approval, processing, and communication, all in real-time. Choose from customizable templates or effortlessly retrieve past forms from our library storage. And, gain access to real-time data and reports, enabling instant insights and quicker decision-making.

Maintain 100% Audit Preparedness

Easily access your permit history and stay updated on regulatory changes, ensuring full compliance with both internal and external regulations. Centralize your permit storage for easy retrieval during audits and incident investigations.

Create a Safe Working Environment

Integrated risk assessments (JSA, TRA, ORM) and real-time data from permits, isolations, hazards, shifts, and SIMOPS enable proactive risk management. Workers can access on-the-go information to ensure they follow procedures correctly, whilst managers benefit from real-time visibility into ongoing and upcoming tasks, enhancing safety and productivity.