Sigmetrix

Sigmetrix - Tolerance Analysis Software

FromSigmetrix

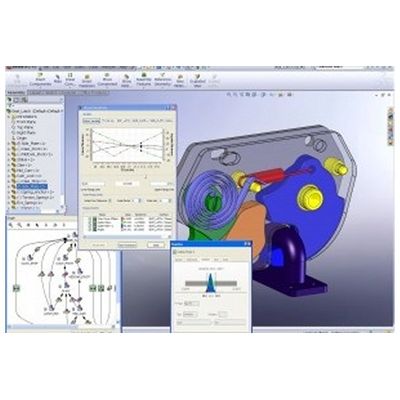

CETOL 6σ provides product development teams with the insight required to confidently release designs to manufacturing. Precise calculation of surface sensitivities exposes the critical-to-quality dimensions in the assembly. Utilizing advanced mathematical solutions, CETOL 6σ accelerates tolerance optimization to achieve robust designs ready for manufacturing.

Most popular related searches

Features

- Changes to tolerances or input statistical distributions immediately update the results.

- Sensitivity plots and visualization tools highlight the impact of each source of variation on the design.

- Contribution plots show what dimensions and tolerances are driving the variation in the design objectives.

- Advisor with 3 classifications of messages provides guidance on the next steps or items that should be reviewed by the user.

- Analyzer presents data in customizable, tabular formats to assist in answering many common technical and business questions.

- Powerful context-sensitive help system with over 40 videos showing how to perform specific tasks.

- Comprehensive and customizable reports.

- Common, open data formats such as XML for storing the CETOL 60 data and CSV and HTML for extracting other data from the analysis results.

- Visual feedback for each item via Interactive highlighting in CAD graphical window when the item is selected.

- Analyses definitions can be saved as a template for application to next-generation designs.

Benefits

- Avoid rework. Design changes that inevitably occur will automatically be reflected in your tolerance studies - no need to fix, or worse, recreate the analyses.

- Optimize the design quickly without having to rerun time-consuming simulation cycles each time an input parameter changes.

- Achieve a better understanding about how your design reacts to real-world variation. Identify and resolve potential problem before they are found in manufacturing or by your customers.

- Start with tolerances that are the least expensive to manufacturing and have CETOL guide you on where to invest in more expensive processes needed to achieve specific product requirements.

- Gain confidence part drawing

- Answer common business questions that arise during manufacturing such as:

- Where is the best application of Statistical Process Control (SPC)?

- Can we use this group of non-compliant parts or must we scrap them?

- Which vendor will provide us the quality we need at the lowest cost?

- Start using the software again quickly after not using it for a long time

- Provide just the right amount of information needed for your target audience to understand your efforts, conclusions, and recommendations.

- Integrate the CETOL data, including results and the data generated to obtain them, with other engineering analysis or quality systems.

- Quickly identify each item of the analysis with visual cues. you make adjustments needed verage what you`ve learne for the new design.