Concepts-NREC - Version MAX-PAC -Turbomachinery CAM Software for Professionals

MAX-PAC is used worldwide by turbomachinery manufacturers, job shops, and 5-axis machine-tool manufacturers who are passionate about producing the highest-quality parts. Manufacturing turbomachinery is challenging. Hard materials, thin blades, tight tolerances, difficult tool access – we’ve been there. And we’ve built MAX-PAC to do the hard work so you don’t have to.

Collision avoidance you can count on

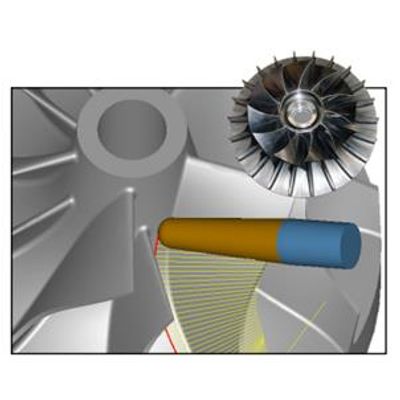

We don’t just solve collision avoidance for individual points. We calculate a safe zone for the entire region, then build the smoothest path through – optimizing machine motion and ensuring a safe toolpath.

Reliable machine motion that is always smooth

Our flank milling solution automatically minimizes surface deviations then gives you the control to fine tune and balance machine motion and accuracy. Designed for use with ruled surface geometries but can also be used to reduce cycle times on all designs when specifications allow it.

For more flexibility, our point milling option lets you accurately machine any blade surface. Ideal for blisks and high-twist geometry.

Integrally shrouded parts are often the most challenging to find tool access. If there is a solution, we will find it. Use box passes for roughing and streamlines for finishing.

When milling single blades and vanes, don’t limit yourself to ball end mills. Take advantage of larger step-overs and reduced cycle times by using corner radius endmills and barrel cutters. Use vector smoothing to improve quality by eliminating rotary reversals.

Rigidity is your friend – especially for roughing operations. Find balance between the flexibility of multi-axis machining and the rigidity of a 3-axis set-up.

Validate programs before you’re at the machine. Simulate material removal and machine motion. Maximize machine utilization and eliminate surprises.

Modify machining instructions to adapt to real-world material conditions such as distortion or positional error.