- Home

- Companies

- Flite Software NI Ltd

- Software

- Two-phase Flow System

Two-phase Flow System

Automatically track fluid phase-state, performs flash calculations, liquid holdup calculations and develops flow regime maps for each pipe segment. Includes eight two-phase correlation methodologies. Highly accurate results developed using a “marching” solution algorithm.

FluidFlow can be used to model fixed or changing vapor quality systems with heat transfer included. Calculation methods available include Lockhart-Martinelli, Friedel, Muller Steinberg and Heck, Drift Flux, Beggs Brill or Chisholm Baroczy.

Comprehensive Fluid and Equipment Databases

Comprehensive databases of over 1200 fluids and over 800 equipment components included as standard. Databases are used extensively in FluidFlow in order to reduce the volume of data entry.

New fluids (including petroleum fractions), fluid mixtures and components can be quickly and easily added.

Databases that describe the performance and limits of fluid equipment items

Library of pipe materials, insulation materials and soil types for buried pipe calculations.

Database of manufacturers, costs, and user-defined areas of application.

Automatic Equipment Sizing Technology

Powerful Automatic Equipment Sizing technology included. FluidFlow will propose the most economical pipe size based on physical property data, capital equipment cost and energy costs.

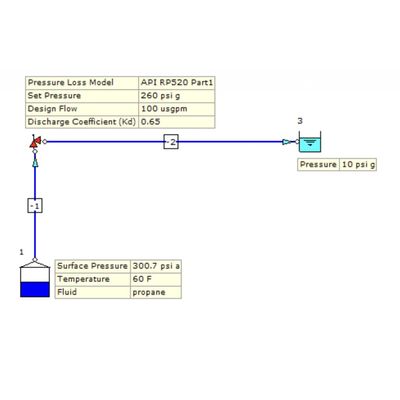

Automatically size relief valves and bursting disks to ISO and API standards.

Pumps can be automatically sized based on either a design flow rate or design pressure rise across the system.

Automatically size pipes or ducts based on any of the following three methods; 1) Economic Velocity, 2) By Velocity and 3) By Pressure Gradient.

Heat Transfer Functionality Included

FluidFlow includes heat transfer functionality on all modules. Engineers can study heat transfer effects at heat exchangers, pipes and junctions. FluidFlow can model shell and tube exchangers, plate exchangers, coils and autoclaves.

Choose from a range of heat transfer options:

Buried pipe calculations.

Pipe heat loss/gain calculation.

Fixed heat transfer rate.

Fixed temperature change.

Ignore heat loss/gain.

Dynamic Analysis

Scripting allows the user to perform dynamic analysis on a model. These time-dependent simulations allow investigation into tank fill/drain times, system pressure as demands vary, control philosophies, and more.

Scripting can be used to perform a wide range of dynamic simulations including:

Analyse system pressure as demands vary.

Investigate system control philosophies.

Evaluate valve performance for variable speed pumps.

Flare stack depressurisation.

Optimise pump and system performance.

Analyse scale build-up in systems and study the effect on flow rate.

Design

- Automatically track fluid phase-state throughout your system, performing flash calculations, liquid holdup calculations and develop flow regime maps for each pipe segment.

- Choose from different two-phase pressure loss correlations or allow FluidFlow to assign the most appropriate correlation based on your design conditions.

- Develop accurate results using a “marching” solution algorithm.

Analyse

- Eliminate data entry errors and enable better understanding of system operating performance.

- Identify any potentially unstable operating conditions and ensure safe designs.

- Monitor steam system quality throughout your piping system.

Size

- Accurately size safety pressure relief valves for two-phase flow conditions.

- Consider flow pattern and superficial velocity as part of evaluation of pipe sizes.

- Avoid the pitfalls of incorrect equipment sizing in two-phase flow systems.

Communicate

- Fully customisable reports allow for effective communication to colleagues, clients and peer review.

- Customise flowsheet to visually communicate key results and design information.

- Develop a clear and transparent design audit trail.