Extende - Ultrasonic Testing Modules with CIVA

UT simulation tools include:

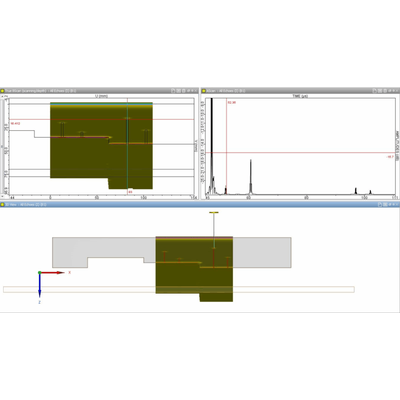

- “Beam computation“: Beam propagation simulation

- “Sensitivity coverage“: To compute sensitivity maps for a given scan plan

- “Inspection Simulation“: Beam interaction with flaws or specimens

User can simulate a whole inspection process (pulse echo, tandem or TOFD) with a wide range of probes (conventional, Phased-Arrays or EMAT), components, and flaws.

Specimen

Parametric geometries and CAD files

The graphical interface allows the user to define the following geometries for the specimen:

- Canonical ones: Planar, cylindrical, conical, spherical

- Predefined component: Nozzle, Butt, bimetallic and Tee Weld templates (13 different bevel profiles available), Turbine blade root and groove, Through Wall Penetration, Elbow, Plates with fasteners

- 2D CAD files containing a profile and generation of the 3D geometry either by translation or rotation of the profile: The profile can be homogeneous or heterogeneous. It can be defined either by CAD import (DXF or IGES format) or directly drawn by the user inside the 2D sketcher of CIVA

- 3D CAD files (IGES or STEP format): Homogeneous or heterogeneous solids, assembled structures with different solids

- Images (such as macrographs) can be imported in CIVA interface to help specimen definition and positioning

- “Depressions” profiles can be described in planar and cylindrical components in order to describe easily local warps

CIVA can also export specimen geometries in IGES format.

Materials

The component can be solid or fluid, homogeneous or made of several layers (e.g. cladding). Each layer may be isotropic or anisotropic, of arbitrary symmetry and orientation. Materials available are not only metallic ones but can also be fiber composites or granular composites (e.g. concrete). A model called “polycrystalline” allows defining monophasic or biphasic grain structure based on the knowledge of the grain size. This model includes the calculation of attenuation laws and structural noise parameters. Finally, simulations on “coarse grains” structures can be done by creation of volumes with the help of Voronoï diagrams. This model allows reproducing beam deviation phenomena, typical of coarse grain structures (e.g. cast stainless steel).

A model of continuously variable anisotropic properties of a volume has been implemented. This has been introduced in order to better account for ultrasound propagation in complex welds. This model is based on the “Ogilvy” theory relative to the grain orientations distribution in austenitic V welds.

Regarding fluids, it is possible for 2D CAD components to account for temperatures gradients in such inhomogeneous fluid media and to account for a flow with speed gradient.

A composite « perspective » (i.e. dedicated environment within CIVA) gathers all features specific for composite materials. It helps to define easily flat or curved composites, stiffeners, stacks of composite plies, ply waviness or delamination. It is also possible to define a pure epoxy layer in between CFRP plies and to account for ultrasound interferences between plies, source of structural noise. Following the options selected, the computation will be then described by semi analytical methods in CIVA UT or in an optional module CIVA FIDEL2D that relies on a coupling between CIVA and a 2D Finite Difference Code called FIDEL 2D and developed by AIRBUS Group Innovations.