- Home

- Companies

- Knowledge Lens

- Software

- UnifyTwin (iLens) - Unifying Human and ...

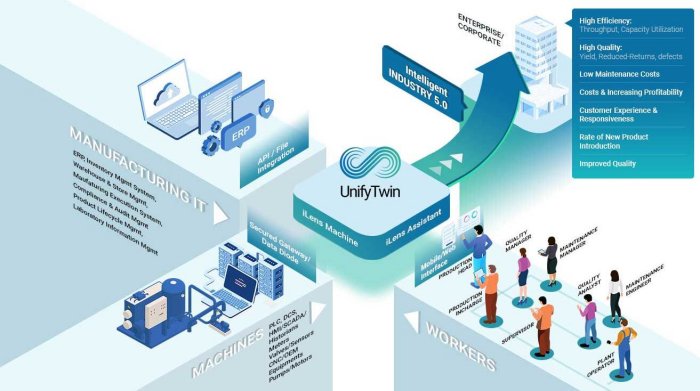

UnifyTwin (iLens) - Unifying Human and Machine Intelligence to enable Sustainable Operations

We are the first Industry 5.0 software company that eliminates digital blind spots and data silos to increase energy efficiency, optimize Asset Efficiency and reduce carbon footprint for Sustainable Operations.

Operate seamlessly on the real-time machine edge-based data along with the data from the information systems of the enterprise and the plant operations, and feed AI-driven contextual views to connected workers.

Serves as a ‘digital friend’ for frontline connected workers to collaborate more efficiently with each other, and use the AI-assisted insights from iLens Machine to accelerate productivity and safety.

Cross-platform Intelligent Apps

- Available as a Native Android and iOS app and through any modern Web browser.

Simplified Connectivity

- Connect to any industrial asset (such as OPC UA/DA, Modbus, EthernetIP, CANBus, Profibus, Profinet etc.) using zero code configuration standards to accelerate the business and operational time to value

Advanced Analytics

- Discover hidden insights using pre-build AI/ML Algorithms for multiple industrial use cases.

Predictive Alerts

- Notify customers of Predictive Maintenance Alerts, Condition Monitoring Alarms, Process Deviation and Quality Alerts

Self Service Visualization

- Easily combine machine and human operations data for comprehensive visualization and interactive process views.

Automated Workflows

- Use industry standard templates to jumpstart customized checklist, SOPs, electronic batch records, logbooks, etc.

360 Degree Asset View

- Centralize digital records from digital twins, maintenance history, service orders, live data, alerts/alarms, anomalies, spare parts history to improve collaboration, transparency and quality of service.

IT-OT Security

- Enable secured connectivity of all OT Assets to experience a highly available and trusted platform.

Unified Data Historian

- Contextualize human and machine data with any manufacturing systems to easily create self-service insights.