- Home

- Companies

- Anaglyph Ltd

- Software

- Version Laminate Tools - Integrated ...

Version Laminate Tools -Integrated Composite Structure Design Software

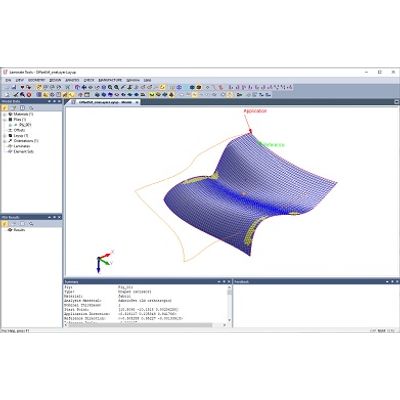

Laminate Tools is an advanced Windows application that seamlessly integrates the design, analysis, and manufacturing processes for composite structures. With a strong focus on composite materials, it acts as a pre- and post-processor for finite element analysis and the generation of manufacturing data, offering cutting-edge drape simulation capabilities for ply definition. The software is designed to connect various disciplines, facilitate data sharing between departments, and ensure a comprehensive understanding of structural designs. Users can import models from a wide range of CAD systems, define materials and ply configurations through an intuitive graphical interface, and utilize proven simulation algorithms to detect manufacturability issues early. It streamlines the generation of accurate analysis models that align with design intentions and permits detailed review using composite failure criteria to quickly identify potential weaknesses. Additionally, Laminate Tools produces essential manufacturing outputs, such as flat patterns and plybooks, enhancing communication with clients and production teams.

Laminate Tools is a powerful software application aimed at the professional composites designer. It addresses the entire Design-Analysis-Check-Manufacture group process of structural design, but focuses on the composite material features. It is a tool that links the various disciplines, communicates original data between departments, ensures proper understanding of the structure, offers in-depth checks and saves valuable team time.

Users import surface models from almost any CAD system and define composite materials, plies and layup using a state-of-the-art graphical user interface. Ply producibility can be evaluated immediately using proven draping simulation algorithms to identify potential manufacturing difficulties, meaning fewer change orders downstream.

Data for finite element analysis purposes are generated seamlessly, ensuring that analysis models reflect the design intent. Results from the finite element analysis can be checked in detail using advanced composites failure criteria, and weak areas identified rapidly.

Manufacturing information such as flat patterns and plybooks are produced to ensure efficient use of manufacturing data. Finally, Laminate Tools can be used as an electronic ply book to communicate the complex structure of composite components and structures to clients, subcontractors and the shop floor.

- It is focused on laminated composites.

- It bridges the Design-Analysis-Manufacture domains.

- It supports industry standard file formats, through the use of Simulayt's proven Layup Technology.

- It offers powerful composites visualisation and becomes invaluable in simply examining a design and pinpointing troublesome areas where composite properties must be reviewed.

- It offers an effective method to communicate information securely and up to date, both within and across organisations.

- It can be used to view past designs for reference purposes, without the need for the original software that was used for the creation, and without running the risk of incurring accidental changes.

- Use selected Finite Element Analysis (FEA) pre-processor applications to create an FE mesh, then use Laminate Tools to drape the mesh with composite fabric and build the layup for the entire structure. Alternatively, use any CAD system to define surfaces and curves, then use Laminate Tools for material draping simulation. In particular, use SOLIDWORKS or Rhinoceros or Femap or HyperMesh and our supplied embedded interface to define plies, then transfer them in a single operation to Laminate Tools.

- Having built a layup with Laminate Tools, use it to convert the ply information to layered material properties suitable for FE Analysis, and use this information with selected FEA applications.

- Post-process the results of FE Analyses in ways that are specific to composite materials, including the ability to examine the individual full global plies.

- Use the ply information for manufacturing: export the flat ply patterns for nesting and cutting, or project, using PlyMatch or laser equipment, the ply outlines on the mould surface during manufacture.

- Simply view, review and approve the structural characteristics during design, and communicate the information digitally across departments or partners / subcontractors. Get the maximum out of a structure, minimise errors and maximise confidence in component performance.