- Home

- Companies

- visTABLE, by plavis GmbH

- Software

- visTABLE - Factory Layout Design ...

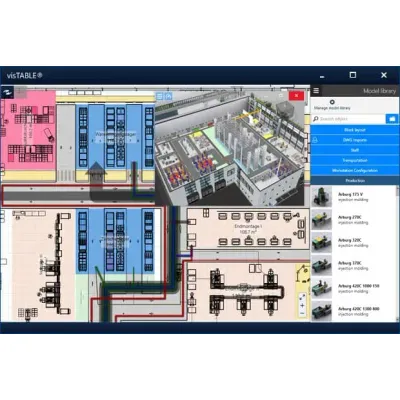

visTABLE - Factory Layout Design Software

visTABLE software is a comprehensive factory layout design tool that merges 2D and 3D modeling with material flow analysis. It enables users to import CAD floor plans and optimize manufacturing layouts by providing data-driven insights and key performance indicators. With capabilities for block layout generation and integration of project stakeholders, the software supports design for both new (greenfield) and existing (brownfield) facilities. It allows for visualization of spatial utilization, distinguishing areas based on function or cost, and evaluating value-adding versus non-value-adding spaces. By converting traditional planning processes into digital workflows, visTABLE® enhances transparency across production and logistics systems, enabling streamlined coordination among departments. All functionalities are included within a single package, promoting ease of use without the need for additional modules.